UL Fire Door Leaf: Engineered Protection from YK Fire Door Supplier

For over two decades, YK Door Industry Co., Ltd. has specialized in crafting UL-certified fire-rated doors trusted by architects and contractors globally. As a leader in fire door manufacturing, we design door leaves that combine rigorous engineering with real-world performance—here’s how our UL-certified cores set the industry standard.

1. Anatomy of a UL Fire Door Leaf

The door leaf—the active panel of a fire door—is more than a barrier. At YK, we engineer it as a multi-layered shield against flames, smoke, and radiant heat.

Core Components:

- Outer Skins: 1.2–1.6mm galvanized steel (G90 coating), precision-rolled for flatness (±0.3mm tolerance).

- Fire-Resistant Core: Mineral wool (density ≥110kg/m³) or ceramic boards (thermal conductivity ≤0.25 W/m·K).

- Edge Reinforcements: Cold-formed steel channels prevent warping under 1,000°C heat (UL 10C tested).

- Vision Panels: Optional UL-listed Keralite® FR glass (5mm thickness, 120-minute integrity).

2. UL Ratings Decoded: Matching Doors to Risks

YK’s UL fire door leaves are tested to withstand 20–120 minutes of direct flame exposure (ASTM E119 curve). Key applications include:

- 60-Minute Doors: Office partitions, hotel corridors.

- 90-Minute Doors: Hospital stairwells, school exits.

- 120-Minute Doors: Industrial boiler rooms, data center walls.

Compliance Essentials:

- Permanent UL label (listing number, rating duration).

- NFPA 80-compliant self-closing mechanisms.

- UL-approved hinges (4.8mm stainless steel pins).

3. Beyond UL: Dual Compliance for Global Projects

While UL standards (UL 10B/10C) govern North America, many clients require alignment with CE fire door ratings (EN 1634). YK’s hybrid solutions bridge both:

| Feature | UL Standard | CE Standard | YK Adaptation |

|---|---|---|---|

| Core Material | Mineral wool | Vermiculite composite | Dual-tested hybrid core |

| Temperature Curve | Rapid-rise ASTM E119 | Gradual EN 1363-1 | Cross-validated insulation |

| Smoke Seals | Intumescent strips | Cold smoke gaskets | Triple-layer graphite/silicone |

Case Study: A Toronto hospital required UL 90-minute doors with CE smoke leakage Class S200. We delivered doors featuring:

- UL-certified cores + EN 1634-3 cold smoke seals.

- Laser-etched dual UL/CE labels on the hinge edge.

4. Custom-Built for Your Facility

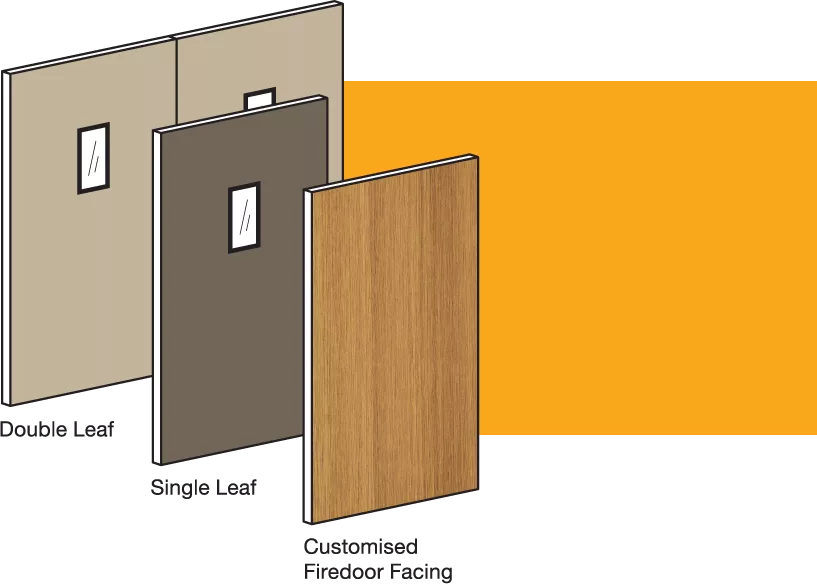

YK tailors UL fire door leaves to project specifics:

- Dimensions: Single leaf (up to 1300x2500mm), double leaf (2000x2400mm).

- Finishes: Electrostatic RAL powder coatings (200+ colors), anti-bacterial laminates for healthcare.

- Hardware Integration: Pre-drilled holes for UL-listed closers (LCN 4040XP) and panic bars.

5. Why YK Outperforms Generic Suppliers

Precision Manufacturing

- Robotic welding ensures ≤0.5mm panel gaps.

- 100% batch testing in our CNAS-accredited lab.

Transparent Certification

- QR codes linked to UL test videos and material certificates.

- Digital logbooks for maintenance tracking.

Global Support

- BIM files (Revit/Archicad) with UL/CE performance data.

- On-site installation training for contractors.

Choose YK for Fire Doors That Work When It Matters

In 2023 alone, our UL-certified door leaves protected 17 high-risk facilities—from Houston chemical plants to Dubai high-rises. With YK, you gain more than compliance; you secure engineered resilience.

Act Now

Contact our fire safety experts today for a free project audit. Let’s build a safer tomorrow—one UL-certified door at a time.

Pingback: Custom steel fireproof door for industrial use - YK | Fire Doors | Fire Windows | Fire Shutters