Why Cold Storage Facilities Require Fire Protection Cold storage warehouses, often designed to preserve perishable goods at extremely low temperatures, are not immune to fire hazards. In fact, the combination of electrical systems, insulation materials, and constant machinery operation can create specific fire risks that differ from those in standard industrial environments. During a recent […]

Tag Archives: Steel fireproof doors

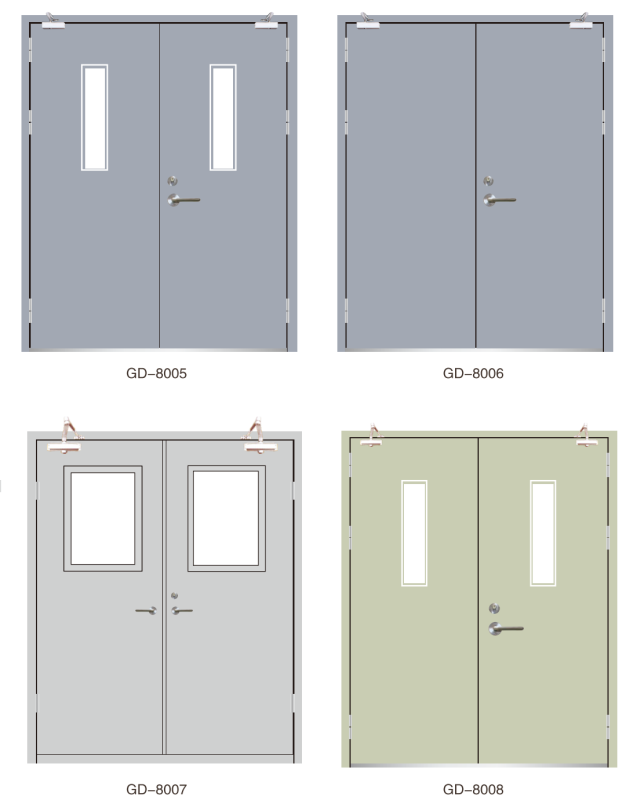

Steel Fireproof Doors: Comprehensive Technical Overview

1. Core Specifications

-

Fire Ratings:

-

30/60/90/120/180 minutes (tested to GB 12955, UL 10C, EN 1634)

-

Must maintain integrity + insulation + smoke blocking

-

-

Standard Sizes:

-

Single leaf: 900-1200mm (W) × 2100-2400mm (H)

-

Double leaf: 1200-1800mm (W) × 2100-2400mm (H)

-

-

Thickness: 45-55mm (standard), up to 70mm (high-security)

-

Weight: 50-80kg (30min) to 120-150kg (180min)

2. Material Composition

| Component | Specification | Key Requirement |

|---|---|---|

| Steel Skin | 18-20 gauge (1.0-1.5mm) | Galvanized (Z275 coating) |

| Fire Core | Mineral wool/vermiculite | Density ≥110kg/m³ |

| Intumescent Seal | Graphite-based | Expands 5-10x at 200°C |

| Frame | 1.5-2.0mm steel | Thermal break required |

3. Manufacturing Process

-

Steel Cutting

-

Laser precision cutting (±0.3mm tolerance)

-

Edge deburring (R0.5mm max)

-

-

Core Assembly

-

Layered structure: Steel → Ceramic mat → Mineral wool → Steel

-

Hydraulic pressing (15kg/cm² @ 150°C for 30min)

-

-

Sealing System

-

3-sided continuous intumescent seal

-

Cold smoke gasket (EPDM rubber)

-

-

Surface Treatment

-

7-stage pretreatment (degreasing → phosphating → passivation)

-

Electrostatic powder coating (60-80μm thickness)

-

4. Performance Testing

-

Fire Test: ISO 834 time-temperature curve

-

30min door must withstand 840°C

-

90min door must withstand 980°C

-

-

Hose Stream Test: Immediate water impact after fire exposure

-

Cyclic Test: 100,000 open/close cycles

5. Certification Marks

-

China: CCCF + GB 12955 label

-

EU: CE + EN 1634 classification

-

North America: UL Listed + hour rating

-

Middle East: ESMA/DCL approval

6. Installation Requirements

-

Frame Anchoring: M10 fire-rated expansion bolts @ 600mm spacing

-

Clearances:

-

Top/sides: 3±0.5mm

-

Threshold: 8-10mm (with automatic drop seal)

-

-

Hardware:

-

Minimum 3 hinges (304 stainless steel)

-

Self-closing device (force 70-110N)

-

7. Maintenance Protocol

| Frequency | Task | Standard |

|---|---|---|

| Quarterly | Seal inspection | GB 12955-2015 |

| Annually | Full operational test | NFPA 80 |

| 5-year | Third-party recertification | Local fire codes |

8. Cost Factors

-

Material (60%): Steel grade (SGCC vs DX51D), core type

-

Certification (20%): Local vs international approvals

-

Features (20%): Glazing, security upgrades, smart systems

9. Industry Trends

-

Smart Integration: IoT sensors for real-time monitoring

-

Hybrid Materials: Aramid fiber reinforcement

-

Green Manufacturing: Chrome-free pretreatment processes

10. Common Failure Modes

-

Seal Degradation: UV exposure → replacement every 5-7 years

-

Hinge Wear: Lubrication required every 50,000 cycles

-

Corrosion: Coastal areas need 316 stainless hardware

This specification meets the most stringent global requirements for life-safety applications. For specialized environments (chemical plants, data centers), additional protections like acid-resistant coatings or EMI shielding may be incorporated.

Map the Codes Before You Buy 1) Identify the governing codes and the room’s occupancy Rule of thumb used by Authorities Having Jurisdiction (AHJs): a 1‑hour fire barrier typically requires a 45‑minute door; a 2‑hour barrier requires a 90‑minute door; a 3‑hour barrier requires a 180‑minute door. Corridor opening protectives are commonly 20‑minute and, in […]

Abstract-Implementation of Steel Fireproof Door This paper outlines the technical process for the installation of steel fireproof doors, emphasizing the expertise of the China fire door factory, Henan Yuankai Door Industry Co., Ltd. It delves into the preparation, tools required, and detailed steps for the successful installation of multi-door access systems for steel fireproof doors. […]

Abstract: The application of sand-grain powder coatings on fire doors often encounters performance issues during bending processes, such as cracking and peeling of the coating. This study focuses on the optimization of polyester resin curing conditions, total resin content, coating thickness, additive ratios, and powder particle size to develop a sand-grain powder coating that resists […]

Optimizing Fire Safety: The Essential Role of Fire-Resistant Expansion Seals in Chinese Fire Doors Fire doors represent a crucial aspect of passive fire protection systems within buildings, serving to effectively isolate the source of a fire, prevent the spread of flames, and thereby safeguard both lives and property. Among the key components of fire doors […]

Steel Fireproof Door Compliance with GB 12955-2008 StandardsAn Industry Perspective from YK Fire Rated Door Manufacturer The adoption of hot-dip galvanized steel sheets in the manufacturing of steel fireproof doors has become increasingly widespread in China—thanks to their outstanding corrosion resistance, attractive finish, and adaptability for post-processing. These attributes, coupled with cost-efficiency and low environmental […]

Technical Standards by YK Fire Rated Door Manufacturer As a professional steel fire door manufacturer, YK Door Industry Co., Ltd. ensures that all custom steel fireproof doors supplied for industrial applications adhere to strict national and project-specific technical standards. The following outlines the key specifications required for compliance and performance in demanding environments. Compliance with […]

Maximizing Safety with Steel Fireproof Doors: A Smart Investment for Your Property When it comes to securing your property and ensuring the safety of its occupants, steel fire-rated doors are one of the best choices available. These doors not only provide robust protection against fire and smoke but also bring style, durability, and long-lasting performance […]

Definition of Steel Fire Doors Definition of Steel Fire Doors:Steel fireproof doors are essential safety features in buildings, constructed using steel raw materials for durability and fire resistance. These doors are composed of door frames, door leaf frames, and door leaf control panels, reinforced with fireproof insulation materials for added safety Understanding Steel Fire Doors: […]