Technical Specifications and Installation Requirements for Chinese Fire Windows

Abstract: Fire windows are critical components in fire protection systems, designed to prevent the spread of fire and smoke within buildings. This paper outlines the technical specifications and installation requirements for Chinese fire windows, with a focus on materials, design standards, and compliance with national regulations. Specific emphasis is placed on the fire resistance ratings of Class A, B, and C fire windows and the importance of proper installation to ensure effectiveness in fire safety applications.

I. Fire Resistance Ratings for Chinese Fire Windows

Chinese fire windows are classified according to their fire resistance limits, which determine their ability to withstand fire for specified periods:

- Class A fire windows: Fire resistance limit of no less than 1.2 hours.

- Class B fire windows: Fire resistance limit of no less than 0.9 hours.

- Class C fire windows: Fire resistance limit of no less than 0.6 hours.

These ratings are crucial for ensuring that fire windows can provide adequate protection in the event of a fire, preventing the spread of flames and smoke across different sections of a building.

II. Technical Specifications

- Materials and Components

- Window Frame Structure: The window frame must be constructed from either a steel or wooden framework with sufficient strength to ensure the integrity and stability of the assembly during a fire.

- Steel Frame and Pressure Strips: The steel frame and pressure strips can be made from galvanized steel or stainless steel plates, with material selection conforming to the standards outlined in GB12955 “General Technical Requirements for Steel Fire Doors,” specifically clause 5.1.

- Wood Frame and Pressure Strips: The wooden frame and pressure strips must adhere to the material standards specified in GB14101 “General Technical Requirements for Wooden Fire Doors,” clause 5.1.1.

- Filling Materials: The interior of both steel and wooden frames should be filled with non-combustible materials to enhance fire resistance.

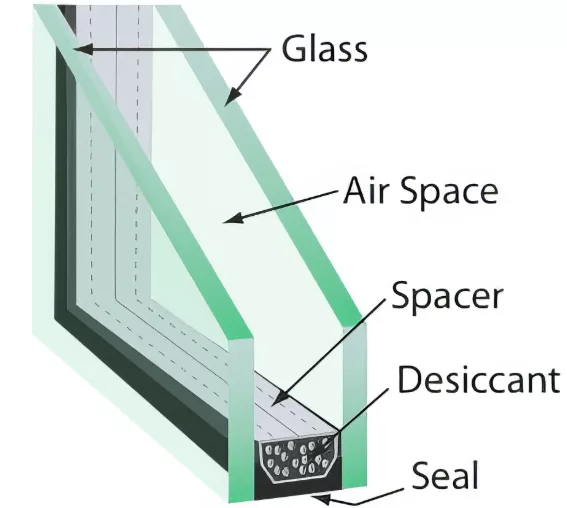

- Fire-Resistant Glass: The glass used in fire windows must be a product that has passed fire resistance performance tests, ensuring that it does not compromise the window’s fire resistance. The light transmittance of the fire-resistant glass should be at least 75% of that of ordinary flat glass of equivalent thickness.

- Sealing Materials: The sealing materials between the frame and fire-resistant glass must be made of fire-retardant materials that can effectively block the passage of smoke and flames during a fire.

- Hardware Fittings: All hardware fittings, including handles and locking mechanisms, should be certified products that have passed rigorous testing to ensure their compatibility and performance in fire scenarios.

III. Installation Requirements

- Acceptance Inspection: Upon delivery, the receiving party must meticulously verify the quantity, specifications, grades, and completeness of all components against the supply contract to ensure compliance with the order.

- Storage Conditions: Fire windows should be stored vertically in a dry indoor environment with appropriate anti-corrosion measures. The glass should be supported and rested against surfaces that will not damage its edges or face.

- Installation Procedures:

- Pre-Installation Inspection: Prior to installation, fire windows must be inspected for any damage incurred during transportation or storage. Any warping, deformation of the window frame or sash, or glass breakage must be repaired before installation can proceed.

- Leveling and Alignment: During installation, it is essential to use a spirit level or plumb line to ensure the window is installed evenly in all directions, maintaining horizontal and vertical alignment.

- Integration with Building Structure: The window frame must be securely integrated with the building structure, using either wooden or metal fasteners to connect it to the wall. For steel window frames, cement mortar must be applied between the frame and the wall, followed by a curing period of at least 24 hours before normal use.

- Hardware Installation: The placement of installation holes for hardware fittings must be precise, allowing for the components to be installed flush and securely, ensuring functional and operational reliability.

- Fire-Resistant Glass Installation: When installing fire-resistant glass, ensure that the gaps around all four sides are even. After positioning the glass, the gaps should be filled with fire-resistant insulation material and sealed with appropriate edge strips.

- Compliance with Standards: Besides adhering to the above requirements, installation must also conform to the relevant provisions of the “Construction and Acceptance Specifications” as mandated by national standards.

CE-Certified EI30 Fire Rated Windows – Energy Efficiency Meets Fire Protection by YK Fire Rated Door Manufacturer

At YK Fire Rated Door Manufacturer, we understand the growing need for fire-rated fenestration systems that not only meet international safety standards but also deliver exceptional thermal performance. Our CE-certified EI30 fire resistant window systems reflect this dual commitment to safety and energy efficiency.

Among our premier offerings is the Energy Concept 90 EI30 fire rated window, a versatile solution that combines advanced fire protection with passive house-level insulation. This system is available in multiple configurations—1-sash and 2-sash side-hung windows with dreh-kip function, balcony and double-balcony doors, as well as fixed panes—tailored for both residential and commercial applications.

The EI30 classification indicates the window’s ability to withstand fire exposure for no less than 30 minutes, maintaining its integrity (E) and insulation (I) properties. In densely built urban environments or close-proximity structures, installing such fire-resistant glazing systems becomes not just code-compliant but vital for occupant safety. As with our stainless steel fire doors and metal fire doors, these fire-rated windows play an essential role in compartmentalizing fire, delaying spread, and protecting egress routes.

With a U-value of 1.2 W/(m²K) for the EC/90 EI30 variant and an exceptional 0.78 W/(m²K) in the standard model, our fire windows support energy-efficient construction while meeting rigorous fire safety benchmarks. These units are fully compatible with passive house designs and exceed many current energy performance regulations.

What sets YK’s fire window systems apart—much like our steel fire resistance doors—is their blend of advanced European engineering, eco-conscious materials, and tailored craftsmanship. Unlike many systems that rely heavily on aluminum components, our environmentally sustainable window designs use natural materials without compromising on durability or fire safety.

Fire window performance standards such as those for the EI30 class fall within broader fireproof window rating systems used across the EU and international markets. At YK, our windows are rigorously tested and classified according to these fire-resistant window ratings, ensuring compliance with both CE directives and global best practices.

Conclusion

The proper selection and installation of Chinese fire windows are vital for ensuring the fire safety of buildings. The technical requirements and installation procedures outlined in this paper are designed to guarantee that fire windows perform their intended function of preventing fire spread effectively. Adherence to these guidelines, along with regular maintenance and inspection, is essential for maintaining the integrity of fire protection systems and ensuring the safety of building occupants. The implementation of these measures will significantly enhance the reliability and performance of fire windows in both residential and commercial applications.

Pingback: Cost of Fire-Resistant Doors - YK | Fire Doors | Fire Windows | Fire Shutters