Fire doors are more than just architectural elements—they are critical life-saving devices. From residential apartments to commercial towers and industrial complexes, fire doors control the spread of flames, smoke, and heat, providing occupants precious time to escape. Understanding fire door classification, selecting the right type, and ensuring proper installation are fundamental to creating safe environments. This guide explores fire door ratings such as FD30, FD60, and FD90, examines different fire door types, and highlights real-world fire door applications across residential, commercial, and industrial settings.

Manufacturers like Henan Yuankai Door Industry Co., Ltd. in China have been delivering certified fire doors worldwide, balancing durability, design, and compliance. Whether you are managing an apartment complex, a high-rise office, or a warehouse, making informed decisions about fire doors can mean the difference between disaster and safety.

Fire Door Classification is a fundamental concept in building safety that goes far beyond simple labels. Each classification, whether FD30, FD60, or FD90, reflects a carefully tested combination of fire resistance, structural integrity, and thermal insulation. These ratings are determined under standardized laboratory conditions, simulating the extreme temperatures and pressures a door might face during a real fire. Understanding these classifications helps architects, engineers, and property managers select doors that not only meet local and international codes but also align with the specific risks of a space. For example, stairwell doors in residential buildings may require FD60 to allow safe evacuation, while utility rooms or server areas might demand FD90 doors to protect critical assets. Materials play a crucial role in classification as well: solid timber offers both aesthetic appeal and fire resistance, steel maximizes durability under high-impact conditions, and glass or aluminum frames provide visibility without sacrificing safety. International standards such as UL in the United States and BS in Europe provide the frameworks for these classifications, ensuring consistency across markets. Manufacturers like Henan Yuankai Door Industry Co., Ltd. have leveraged these standards to produce doors that perform reliably in diverse applications, from apartment complexes in North America to commercial facilities in Africa and Latin America. Ultimately, understanding fire door classification allows decision-makers to integrate safety, design, and functionality, creating environments that protect both lives and property without compromise.

Understanding Fire Door Ratings: The Language of Safety

When you walk through a commercial building, hospital, or school, you rarely stop to think about the fire doors around you. Yet every one of those doors carries a rating that could mean the difference between a controlled incident and a disaster. Fire door classifications aren’t just numbers on a label—they are the industry’s way of translating safety into measurable standards. To understand how and where fire doors should be applied, you first need to grasp how those ratings are defined.

Decoding the Label: What FD30, FD60, and FD90 Really Mean

At first glance, the designations FD30, FD60, or FD90 sound like obscure technical codes. In reality, they are shorthand for how long a fire door can withstand flames before failing. An FD30 door is designed to resist fire for 30 minutes, while FD60 and FD90 hold out for an hour and an hour and a half, respectively. But those minutes aren’t arbitrary; they give building occupants valuable time to escape and give firefighters a chance to contain the blaze.

The way these labels are used also speaks to the building’s purpose. For example, in an office block with high foot traffic, FD60 doors are often a baseline requirement. In residential developments or smaller educational spaces, FD30 may be sufficient. Choosing the right rating isn’t only about compliance—it’s about fitting safety to the rhythm of how people actually use a space.

Beyond Time: How Ratings Also Indicate Integrity and Insulation

It’s easy to assume that the rating is simply a stopwatch measure, but it actually reflects deeper qualities. A fire door is tested not only for how long it can hold back flames, but also for how long it can maintain structural integrity and insulation. Integrity is about keeping the door intact under intense heat without cracking or warping, while insulation measures its ability to stop dangerous heat transfer to the other side.

This distinction matters. A poorly insulated door may technically last 60 minutes against flames, but if the surface becomes so hot it ignites nearby materials, the protection is compromised. When U.S. safety officials write codes, or when international suppliers like Henan Yuankai Door Industry Co., Ltd. design fire doors for export, these dual aspects of performance are critical benchmarks.

Global Standards: A Brief Look at UL (US) and BS (EU) Ratings

In the United States, the UL (Underwriters Laboratories) rating system is the gold standard, and it focuses heavily on fire endurance tests. In Europe, the BS (British Standards) system categorizes fire resistance using a slightly different framework, often aligning with terms like EI (integrity and insulation). While the numbers may vary, both systems aim at the same outcome: ensuring the door buys enough time for people to escape and firefighters to act.

For international manufacturers, understanding both systems is essential. A company in China, such as Henan Yuankai Door Industry Co., Ltd., must design products that can be tested and certified under multiple rating systems to remain competitive in export markets. That dual compliance is why their doors appear in projects not just in China, but also across Southeast Asia, Europe, and North America.

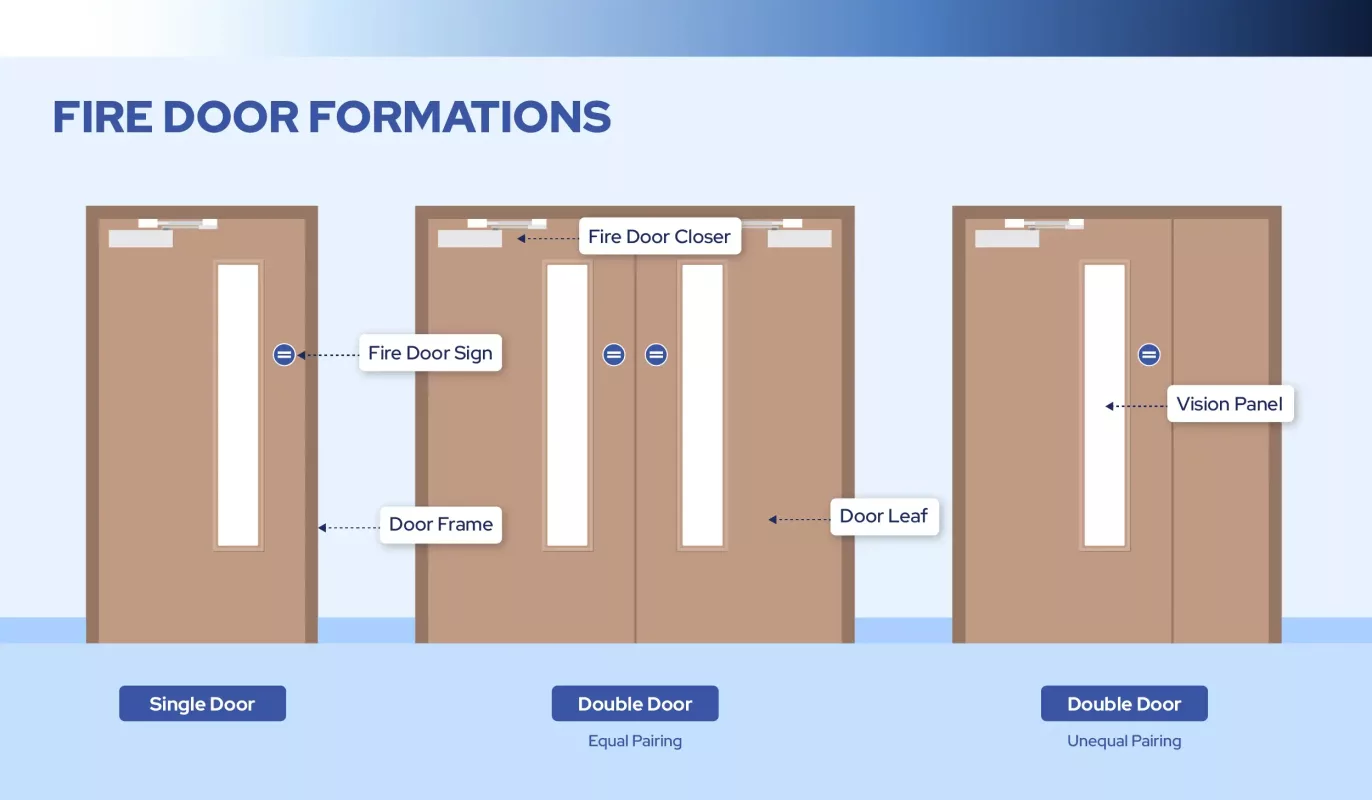

A Guide to Common Fire Door Types and Their Core Materials

Selecting the right fire door isn’t only about meeting code requirements—it’s about matching the material to the building’s purpose, its daily traffic, and even its architectural character. Each type of fire door brings its own balance of performance, aesthetics, and cost. Understanding these differences helps decision-makers—from architects to facility managers—avoid costly mistakes and ensure lasting protection.

Solid Timber Doors: The Classic Choice for Aesthetics and Performance

Solid timber has long been the go-to option for projects where safety needs to blend seamlessly with design. These doors offer excellent fire resistance, often up to 60 minutes or more when manufactured to strict standards, while maintaining the warm look that many residential and office projects prefer. What sets timber apart is its ability to be customized—finishes, veneers, and stains can be matched to existing interiors, making it an ideal choice for upscale apartments, hotels, and educational facilities.

Still, timber doors aren’t just about appearances. Modern fire-rated wooden doors use engineered cores and layers of fire-resistant materials, meaning they perform far better than older models. Many international suppliers, including Henan Yuankai Door Industry Co., Ltd. in China, have mastered the balance between craftsmanship and compliance, producing timber fire doors that pass stringent tests while still appealing to design-conscious buyers abroad.

Steel Doors: Maximum Durability for High-Traffic and Industrial Use

In spaces like warehouses, hospitals, or manufacturing plants, steel is often the material of choice. Steel fire doors are valued for their resilience—they don’t warp under heat, they withstand heavy impacts, and they stand up to constant use in areas where doors may be opened and closed hundreds of times a day. Their fire ratings often reach FD90 or beyond, making them suitable for environments where every extra minute counts.

Aesthetics may not be the first priority here, but steel doors have evolved too. Powder-coated finishes, stainless steel options, and even hybrid designs allow them to blend into modern commercial architecture. U.S. building managers often appreciate that steel doors not only satisfy UL fire rating requirements but also add a layer of security against forced entry—an important dual function in retail and institutional settings.

Glass and Aluminum Doors: Modern Design with Unobstructed Visibility

For contemporary offices, schools, and healthcare environments, visibility is as important as safety. Glass fire doors framed with aluminum deliver both. With advanced fire-rated glazing, these doors can hold back flames for 30, 60, or even 120 minutes, depending on the specification, without compromising transparency. They are especially valued in settings where evacuation routes must remain clear and supervision is key, such as hospital corridors or classrooms.

Aluminum frames keep the structure lightweight and sleek, while the glass panels preserve natural light and open sightlines. This makes them not only functional but also a design statement, especially in projects aiming for a modern or minimalist aesthetic. International manufacturers like Henan Yuankai Door Industry Co., Ltd. have invested heavily in expanding their glass-and-aluminum fire door lines, catering to global demand for safer yet more visually appealing building solutions.

Matching the Door to the Danger: Residential Applications

When we talk about fire doors, most people picture commercial towers or industrial sites, but the truth is that fire protection begins at home. Residential environments pose unique risks—kitchens, garages, and multi-family apartments all have different fire dynamics. A carefully selected fire door doesn’t just meet code; it creates a safer living environment for everyday families. And because housing construction varies so widely between regions—from American high-rises to African single-story dwellings—the application of fire doors has to be matched thoughtfully to each type of residential risk.

Protecting Escape Routes: Doors to Stairwells and Exit Passages

In multi-story housing, the most vulnerable point during a fire is not the living unit itself but the shared escape routes. Stairwells and corridors must stay clear of flames and smoke long enough for residents to evacuate. In the U.S., building codes often require FD60-rated doors on stairwell entrances, ensuring that the path to safety remains accessible even if a unit fire rages nearby.

Similar logic applies elsewhere. In densely populated apartment complexes in Nairobi or Lagos, where evacuation infrastructure can be less robust, the reliability of a stairwell fire door is even more critical. The difference between a properly rated door and a non-rated one may be the only factor that prevents smoke inhalation casualties. International suppliers, including Henan Yuankai Door Industry Co., Ltd., have recognized this demand, exporting FD60 and FD90-rated doors specifically to meet the growing urban housing market in Africa and Latin America.

Containing Risks: Doors for Garages, Kitchens, and Utility Rooms

Not every residential fire begins in a living room. Many start in the places we overlook—garages packed with flammable materials, kitchens with high heat sources, or utility rooms where electrical systems converge. A fire door in these spaces isn’t about aesthetics; it’s about creating a buffer zone that isolates the hazard before it spreads.

In the U.S., garage-to-house fire doors are often mandated to carry a minimum of 20-minute ratings, but many homeowners opt for higher ratings for added peace of mind. Across Latin America, where informal housing sometimes blends cooking areas with living quarters, fire-rated doors are being introduced as part of affordable housing initiatives. Manufacturers like Yuankai, working with local distributors, are helping bridge the gap by offering cost-effective steel and timber doors that still meet international safety benchmarks.

Apartment Front Doors: Safeguarding Individual Living Units

For tenants in apartment buildings, the front door is more than an entryway—it’s the first line of defense in a fire. Apartment entry doors must resist fire and block smoke long enough to protect residents while they wait for rescue or find a safe evacuation route. In American cities, FD60 doors are the common standard, but in high-rise developments in Brazil or Mexico, stricter requirements are emerging as governments learn from tragic past fires.

What’s striking is how front door requirements reflect social realities. In the U.S., emphasis is placed on both security and fire protection, leading to heavy-duty steel or composite designs. In parts of Africa, affordability drives demand for simpler but still certified wooden fire doors. Henan Yuankai Door Industry Co., Ltd. has adapted by offering ranges that balance cost with compliance, giving property developers the ability to install doors that protect lives without breaking project budgets.

Commercial and Industrial Fire Door Solutions

If residential fire protection is about personal safety, commercial and industrial fire doors are about managing risk at scale. These environments bring larger crowds, higher-value assets, and often, more volatile hazards. A hotel, office tower, or factory doesn’t just need a door that resists fire—it needs a system that integrates with evacuation planning, insurance requirements, and long-term operational resilience. The choice of fire door here is as much about business continuity as it is about saving lives.

Corridor and Compartment Doors in Offices and Hotels

Walk into a modern office building or hotel, and you’ll find long corridors and expansive open spaces that make design attractive but also create vulnerabilities. Fire doors in these settings don’t just close off one room; they act as compartmental barriers, stopping fire and smoke from sweeping through an entire floor in minutes. In the United States, codes often demand FD60 or higher for these partitions, while in high-rise hotels in Latin America, stricter FD90 doors are sometimes specified because of longer evacuation times.

There’s also a design element that cannot be ignored. In hotels, guests expect a sense of comfort and elegance, not the cold look of an industrial steel door. That’s why manufacturers, including Henan Yuankai Door Industry Co., Ltd., have invested in wood-veneered or glazed fire doors that deliver both aesthetics and compliance. A corridor door in a five-star hotel must not only withstand fire but also contribute to the interior design narrative. That dual demand makes this category particularly challenging for suppliers.

High-Risk Area Protection: Server Rooms, Labs, and Warehouses

Some areas of a building are far more dangerous than others. Server rooms house not just hardware but data worth millions; labs may contain chemicals that react violently with heat; warehouses often store flammable stock in bulk. Fire doors for these spaces must provide extended protection—not just holding flames back for an hour but also limiting smoke leakage and heat transmission that could damage sensitive equipment.

In the U.S., UL-rated doors with smoke seals are commonly specified for IT and pharmaceutical facilities. Meanwhile, in rapidly growing African economies, industrial parks are being built with fire-rated steel doors designed to meet both local codes and international insurance requirements. This is where global suppliers like Yuankai gain traction—they can ship high-integrity doors tested against multiple standards, making them suitable for export to diverse markets. A warehouse in Houston and a chemical lab in Johannesburg may look different, but the need for airtight fire containment unites them.

Specialized Doors for Factories and Loading Docks

Factories and loading docks present a different challenge altogether. Unlike office or hotel settings, these spaces require doors that combine fire resistance with durability against physical stress. Heavy machinery, forklifts, and constant movement mean the doors must withstand impacts while still delivering on fire performance. In addition, many loading docks are exposed to weather, requiring finishes and materials that don’t degrade when exposed to moisture or temperature swings.

A well-designed factory fire door is not simply a piece of safety equipment; it becomes part of the facility’s operational rhythm. In automotive plants in Detroit, for example, rolling fire shutters are installed to divide production lines while allowing quick equipment access. In textile factories in Ethiopia, hinged steel fire doors protect storage areas without interrupting workflow. Yuankai has positioned itself as a practical partner here, offering ruggedized fire doors built for industrial use that balance fire ratings with the wear-and-tear demands of daily production cycles.

Beyond the Door: Hardware, Installation, and Compliance

A fire door’s rating—FD30, FD60, or FD90—is only one piece of the puzzle. Even the most robust door can fail if paired with substandard hardware, improperly installed, or misaligned with local building codes. In commercial and residential contexts alike, the entire system—including hinges, closers, seals, and installation—plays a critical role in delivering real-world protection. Understanding these elements is essential for architects, developers, and property managers who want to move beyond mere compliance and achieve genuine fire safety.

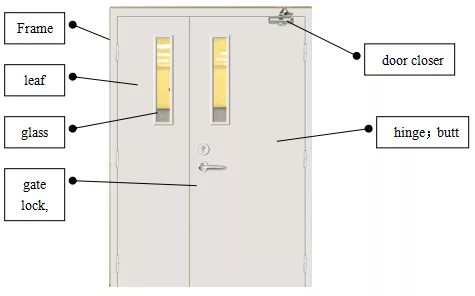

Why Certified Hinges, Closers, and Seals are Non-Negotiable

Every component attached to a fire door must meet rigorous standards. Certified hinges ensure that the door remains securely in place under extreme heat. Closers control the door’s swing speed, guaranteeing that it shuts completely even if someone leaves it ajar. Smoke and intumescent seals expand under heat to fill gaps and prevent dangerous gases from spreading. Using off-the-shelf hardware or ignoring certification can turn an FD60-rated door into a weak point in your fire safety plan.

For example, in apartment complexes in Miami or Johannesburg, doors with uncertified hardware may close partially or warp during a fire, allowing smoke to reach stairwells or hallways in minutes. Manufacturers like Henan Yuankai Door Industry Co., Ltd. provide complete fire door assemblies with certified components, ensuring that the rated performance is preserved throughout the life of the building.

The Critical Impact of Professional Installation on Performance

Even the best fire door can fail if installed incorrectly. Proper installation includes correct alignment within the frame, appropriate clearances, and secure attachment of all hardware. A poorly fitted door can leave gaps, reduce insulation effectiveness, and compromise integrity under fire conditions.

Professional installers also understand the subtleties of various environments. In a high-rise office in New York, slight misalignment may go unnoticed during daily use but could prove catastrophic in a fire. Similarly, in industrial warehouses in São Paulo, repeated door impacts demand both precise alignment and reinforced frames to maintain fire resistance. Investing in professional installation ensures that the fire door performs as tested and rated.

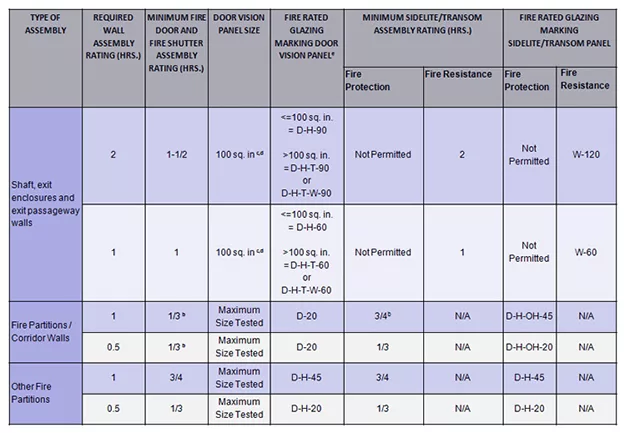

Ensuring Your Door Assembly Meets Local Building Codes

Fire door compliance is not one-size-fits-all. Codes like NFPA 80, the International Building Code (IBC), and local amendments specify requirements for rating, hardware, and installation. Even a door meeting UL or BS standards may fall short if local regulations differ.

For residential buildings, codes dictate where FD30 or FD60 doors are required—for example, in stairwells, garages, and apartment entryways. In commercial properties, FD90 doors may be mandatory for server rooms, laboratories, or manufacturing zones. By aligning the door, hardware, and installation with local codes, property owners reduce liability, improve insurance outcomes, and, most importantly, protect occupants.

Conclusion

Selecting the right fire door requires more than checking a label—it involves understanding the rating, material, and application scenario, and ensuring that hardware, installation, and compliance align with local and international standards. From timber FD30 doors in apartment stairwells to steel FD90 doors in warehouses and laboratories, each choice must reflect the specific risks of its environment.

Fire safety is a system, not a single component. Doors, hinges, closers, seals, and installation practices all work together to create protection that lasts for decades. Leveraging the expertise of experienced suppliers like Henan Yuankai Door Industry Co., Ltd. ensures that buildings meet both design and safety goals, whether in the U.S., Africa, or Latin America.

To simplify the selection process, download our Quick Fire Door Selection Guide PDF or contact an expert to discuss complex projects and customized solutions. Every decision you make today can safeguard lives tomorrow.

Frequently Asked Questions (FAQ)

Q1: What do FD30, FD60, and FD90 ratings mean?

A: These ratings indicate the fire resistance duration of a door—FD30 for 30 minutes, FD60 for 60 minutes, and FD90 for 90 minutes. They also reflect the door’s integrity and insulation performance under fire conditions.

Q2: How do I choose the right fire door for my apartment or house?

A: Consider the risk area: stairwells, corridors, garages, and apartment entry doors have different requirements. FD30 doors are common for interior passages, while FD60 may be required for stairwells and entry doors.

Q3: What fire door materials are available and what are their benefits?

A: Solid timber doors provide aesthetics and moderate fire resistance; steel doors offer high durability for industrial or high-traffic areas; glass and aluminum doors combine fire protection with transparency and modern design.

Q4: Why is professional installation important for fire doors?

A: Even the highest-rated door can fail if installed incorrectly. Professional installation ensures proper alignment, hardware attachment, and compliance with local codes such as NFPA 80 and IBC.

Q5: What should I look for in fire door hardware?

A: Certified hinges, closers, and intumescent seals are essential. They ensure the door closes fully, resists heat, and prevents smoke leakage, preserving the rated fire performance.

Q6: Can I use fire doors from international suppliers?

A: Yes. Companies like Henan Yuankai Door Industry Co., Ltd. provide doors tested against international standards, making them suitable for U.S., African, and Latin American markets, as long as local codes are also met.