Product Overview

A bulletproof door is more than a physical barrier; it is a complete security solution designed to withstand ballistic impact, forced entry attempts, and extreme operational pressures. Unlike ordinary fire doors or anti-theft doors, which primarily address fire resistance or burglary deterrence, bulletproof doors are engineered to stop high-velocity projectiles while preserving structural integrity and safe evacuation functions. This dual protection—against both armed assault and environmental risks—makes them essential in facilities where security cannot be compromised.

How Bulletproof Door Reducing Long-Term Costs for Real Estate Developers

In today’s security-conscious environment, demand for armored security doors has expanded well beyond government and military facilities. Banks and financial institutions install bulletproof doors in vaults and cash-handling areas to protect personnel and assets. Government buildings and embassies adopt ballistic resistant doors to maintain resilience against armed attacks. High-net-worth individuals and luxury homeowners increasingly specify bulletproof doors in private residences and villas, integrating advanced finishes so that protection is discreet but uncompromising. Even data centers and critical infrastructure sites are turning to ballistic solutions as part of broader risk management strategies.

The distinction between bulletproof doors and conventional security products lies in rigorous testing and certification. While a standard fire-rated door is tested for resistance to flames and smoke, a ballistic resistant door must endure direct gunfire under international standards such as UL 752, EN 1522/1523, or NIJ ratings. Each certified door provides a defined level of protection—from handgun rounds to high-powered rifles—giving contractors and end users confidence in performance under hostile conditions. For buyers, this difference is not theoretical; it translates into lives protected, assets secured, and insurance requirements satisfied.

As an experienced bulletproof door supplier, YK Door Industry brings together material innovation, ballistic testing, and customization capabilities. Our doors combine high-strength steel, composite armor panels, and laminated ballistic glass, allowing each unit to be tailored for both function and aesthetics. The result is an armored security door that integrates seamlessly into architectural design while meeting the most demanding resistance standards. This balance of performance, certification, and design flexibility makes bulletproof doors a trusted choice for contractors, developers, and facility managers who require proven protection without compromise.

Key Features

-

Ballistic Resistance Standards

Bulletproof doors are classified under internationally recognized standards such as EN 1522/1523 (FB1–FB7), UL 752 (Level 1–10), and NIJ (Level II–IV). Each level corresponds to protection against specific calibers, ranging from 9mm handguns to 7.62mm NATO rifles. For example, UL 752 Level 3 is tested against .44 Magnum rounds, while EN FB6 resists 5.56×45 mm and 7.62×51 mm rifles. Contractors in Brazil often specify EI90 fire resistance combined with UL 752 Level 5 ballistic certification for financial institutions and government offices. -

Door Leaf Materials

Bulletproof doors combine high-strength steel plates, armored composites, and laminated ballistic glass. Standard models use 5–12 mm ballistic steel, while premium models integrate multi-layer composites to reduce weight without compromising protection. Laminated ballistic glass panels, usually 24–60 mm thick, are tested to the same level as the opaque leaf to maintain uniform resistance. -

Reinforced Door Frame & Locking Mechanism

The frame is engineered with welded steel reinforcements and optional multi-point locking systems. Advanced models feature automatic deadbolt systems that engage at multiple points across the jamb, resisting pry attacks and blast overpressure. In high-security vaults, frames may include interlocking anti-breach profiles that prevent the leaf from being forced open. -

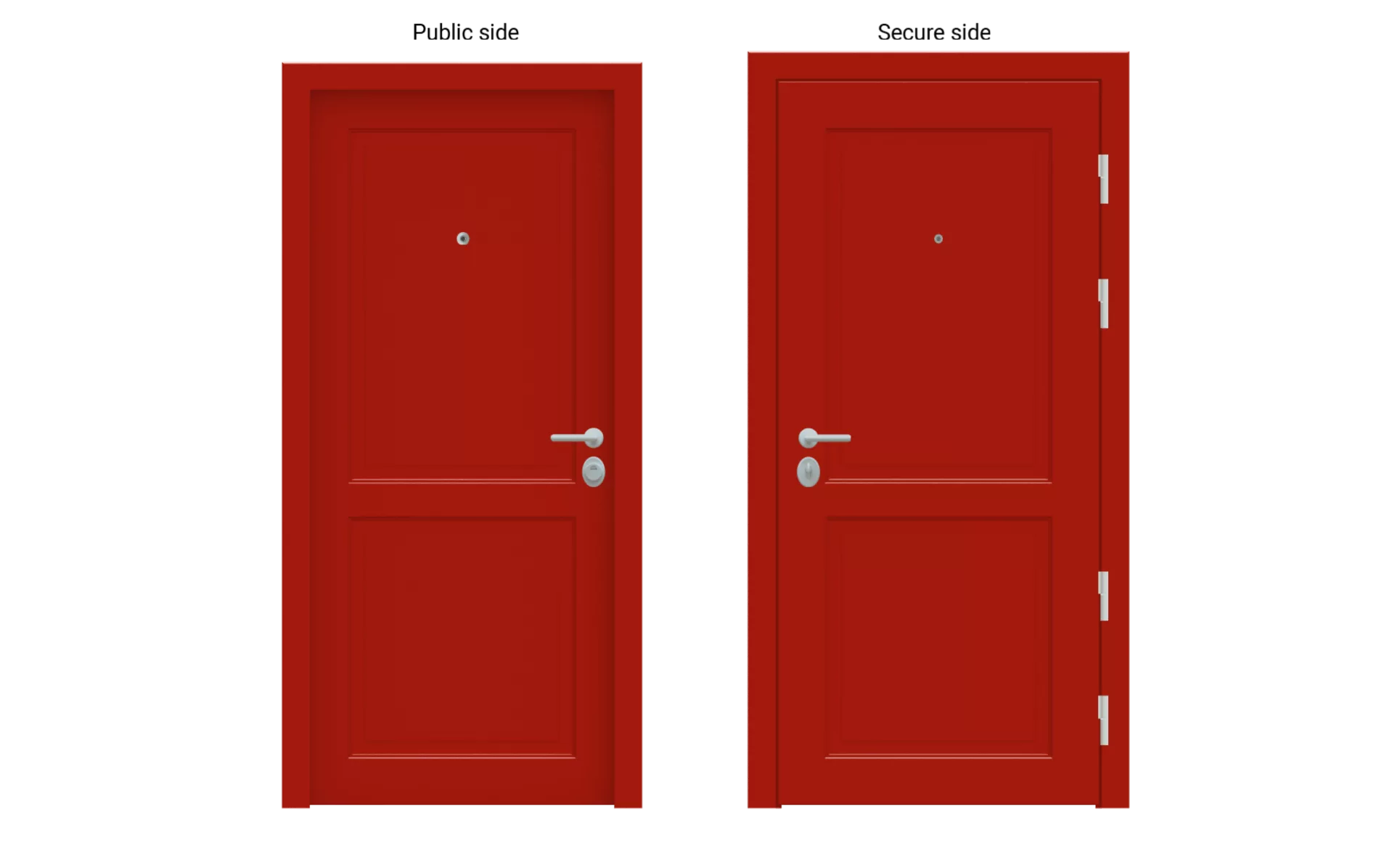

Design & Finish Options

While performance is non-negotiable, modern armored security doors are available with a wide range of finishes to match architectural environments. Choices include wood veneer for luxury residences, powder-coated finishes for offices and industrial facilities, and stainless-steel cladding for coastal or high-humidity regions. Many premium projects in São Paulo and Rio de Janeiro require custom veneer finishes so that bulletproof doors blend seamlessly with interior décor. -

Additional Functional Features

Beyond ballistic protection, bulletproof doors often integrate:-

Fire resistance (tested up to EI60/EI90 under ABNT standards).

-

Anti-burglary reinforcement (tested under EN 1627 RC3–RC6).

-

Acoustic insulation (up to 42 dB reduction with composite cores).

-

Blast resistance (pressure-tested for energy facilities and embassies).

-

Smart integration with biometric locks, electromagnetic closers, and building management systems.

-

Feature Summary & Certifications

| Category | Specifications / Data |

|---|---|

| Ballistic Standards | EN 1522/1523 FB1–FB7, UL 752 Levels 1–10, NIJ II–IV |

| Fire Resistance | EI30–EI90 (ABNT tested, INMETRO certified) |

| Anti-Burglary Class | EN 1627 RC3–RC6 |

| Door Leaf | 5–12 mm ballistic steel, composite armor panels, 24–60 mm laminated ballistic glass |

| Frame Construction | Steel reinforcement, interlocking anti-breach design, multi-point locking (3–10 points) |

| Surface Finish | Wood veneer, powder coating, stainless steel, custom decorative panels |

| Additional Features | Acoustic insulation (up to 42 dB), blast-tested models, biometric/EM lock integration |

| Certification Bodies | ABNT (Brazil), INMETRO (Brazil), UL (U.S.), NIJ (U.S.), EN (EU accredited labs) |

| Testing Facilities | Full-scale ballistic testing under UL/EN protocols; fire testing in accredited labs |

| Supplier Capability | YK Door Industry – experienced bulletproof door supplier with custom export solutions |

Technical Specifications

The following specifications illustrate the standard and customizable options available for bulletproof doors. All configurations can be adapted to meet Brazilian ABNT requirements in combination with international ballistic standards.

| Category | Specification Details |

|---|---|

| Size Range | Standard single leaf: 900 × 2100 mm to 1200 × 2400 mm Double leaf: up to 2400 × 3000 mm Custom oversized vault doors available on request |

| Material Thickness | Ballistic steel plates: 5–12 mm Composite armored cores: multilayer (15–40 mm) Reinforced frame sections: 2–4 mm structural steel |

| Ballistic Ratings | EN 1522/1523: FB4 (handguns) – FB7 (rifles) UL 752: Level 3 (.44 Magnum), Level 5 (7.62 mm rifle), Level 8 (5.56 mm rifle) NIJ: Level II – IV |

| Locking Systems | Mechanical multi-point locks (3–10 points) Electronic keypad locks Biometric and fingerprint recognition systems Optional integration with access control / smart building systems |

| Viewing Panels | Laminated ballistic glass panels: 24–60 mm thickness Certified to the same level as opaque leaf (EN FB4–FB6 / UL 752 L3–L8) Optional fire-rated glass integration |

| Surface Finishes | Powder-coated steel, stainless steel cladding, natural wood veneer, custom decorative panels |

| Fire Resistance | EI30–EI90 (tested under ABNT and INMETRO certification) |

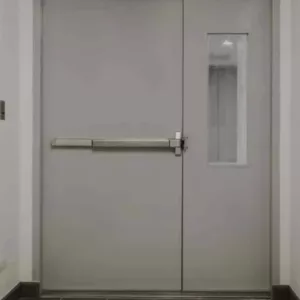

| Additional Options | Acoustic insulation up to 42 dB Blast resistance (pressure-tested) Emergency egress hardware (panic bars) |

4. Applications

The demand for bulletproof doors has grown globally as governments, businesses, and private clients face rising security challenges. Armored security doors today are installed not only in high-risk political zones but also in financial hubs, luxury real estate, and industrial sites. Below are key sectors with representative projects from Russia, Africa, and international markets.

Government and Military Buildings

Government facilities and military compounds are among the most traditional users of ballistic resistant doors. They require systems capable of withstanding both firearm assaults and blast pressure.

-

In Moscow, several administrative offices of the Ministry of Defense upgraded entrances with EN FB6 steel bulletproof doors, ensuring resistance to 7.62 mm NATO rounds.

-

A police command center in Johannesburg, South Africa, installed armored double-leaf doors with multi-point locking systems, after a series of armed attacks in 2022.

-

Military depots in Angola deployed UL 752 Level 8 ballistic resistant doors with reinforced hinges to secure ammunition bunkers.

These projects underline the role of bulletproof door suppliers as part of national defense strategies.

Banks, Vaults, and Cash-Handling Facilities

Financial institutions across Russia and Africa invest heavily in armored security doors to protect cash and staff in high-crime environments.

-

Sberbank branches in Moscow upgraded teller areas with NIJ Level III bulletproof doors, integrating them with biometric access systems.

-

In Lagos, Nigeria, two major commercial banks installed ballistic resistant doors with laminated vision panels, combining visibility with security.

-

A private cash logistics company in Kenya introduced UL 752 Level 5 armored doors for vault facilities, ensuring compliance with global insurance requirements.

These cases show that bulletproof doors are a core part of financial resilience in both developed and emerging economies.

Luxury Homes, Villas, and Private Estates

The luxury real estate sector is a rapidly expanding market for bulletproof doors, especially in regions with rising concerns over personal safety.

-

Private villas in Rublyovka, Moscow’s elite district, feature wood-veneered UL 752 Level 3 bulletproof doors, offering discreet yet certified protection.

-

A gated estate in Cape Town, South Africa, mandated armored security doors with EI60 fire resistance in all new homes, addressing both fire and ballistic risks.

-

High-net-worth families in Nairobi increasingly install ballistic resistant doors with fingerprint locks, ensuring safety without compromising aesthetics.

This trend shows how bulletproof door suppliers adapt their products to combine security with architectural design.

Industrial Plants and Research Facilities

Industrial parks and confidential laboratories use armored security doors to secure sensitive zones from both intrusion and sabotage.

-

A nuclear research facility near St. Petersburg installed EN FB7 ballistic resistant doors in 2023, providing protection against armor-piercing ammunition.

-

A diamond mining facility in Botswana upgraded its central control rooms with blast- and bulletproof steel doors, enhancing resilience against sabotage attempts.

-

In Egypt, a petrochemical plant adopted UL 752 Level 8 armored security doors, tested for both ballistic and blast resistance.

These cases highlight how bulletproof doors are used not only for safety but also for asset and intellectual property protection.

Data Centers and Critical Infrastructure

As digital infrastructure expands worldwide, bulletproof doors are becoming a mandatory part of physical security strategies.

-

A Tier IV data center in Moscow integrated EI120 ballistic resistant doors with electromagnetic locks, linked to a central building management system.

-

South African energy companies are increasingly specifying ballistic resistant doors with blast ratings for substation and control room protection.

-

A major telecommunications hub in Nigeria installed UL 752 Level 5 armored doors, ensuring compliance with global cybersecurity and physical security standards.

These projects show how armored security doors are evolving from niche products into mainstream components of infrastructure resilience.

5. Certifications & Standards

The credibility of bulletproof doors depends on independent testing and certification under recognized ballistic resistance standards. Contractors and end users in sectors such as banking, government, and critical infrastructure expect suppliers to provide verifiable certificates, ensuring that each door performs exactly as specified.

European Standard – EN 1522/1523

The EN 1522/1523 standard is widely used across Europe and many international markets. It defines ballistic classifications from FB1 to FB7, each corresponding to specific firearms and ammunition.

-

FB4: Handgun resistance (.44 Magnum).

-

FB6: Resistance to high-powered rifles such as 5.56×45 mm and 7.62×51 mm NATO.

-

FB7: Highest level, designed to resist armor-piercing ammunition.

In Russia, many government and research facilities specify EN FB6 and FB7 doors to meet defense and industrial requirements.

American Standard – UL 752

The UL 752 standard, developed in the United States, is one of the most recognized certifications for armored security doors. It ranges from Level 1 to Level 10, testing against progressively more powerful ammunition.

-

Level 3: Tested against .44 Magnum.

-

Level 5: Resistant to 7.62 mm rifle rounds.

-

Level 8: Designed for 5.56 mm and 7.62 mm rifle fire, commonly required in financial and government facilities.

In Africa, banks and cash logistics firms often require UL 752 Level 5 or Level 8 bulletproof doors to secure vaults and teller areas.

U.S. National Institute of Justice (NIJ)

The NIJ ballistic resistance standard is applied in law enforcement and government procurement. It covers Level II, III, and IV, with Level IV offering protection against armor-piercing rounds. NIJ-certified ballistic resistant doors are increasingly specified by security agencies in high-risk regions, including embassies and police command centers.

Chinese Ministry of Public Security Certification

For projects sourced from Asia, many bulletproof doors also carry testing reports from the Chinese Ministry of Public Security (MPS). These reports validate ballistic performance under national test protocols and are often combined with fire resistance certifications, making them suitable for export to markets that demand both ballistic and fire-rated performance.

Laboratory Ballistic Testing

Beyond published standards, custom laboratory ballistic testing is frequently required in tenders. Reputable bulletproof door suppliers like YK Door Industry cooperate with accredited testing facilities to perform project-specific ballistic tests. Certificates can be issued under the contractor’s name, giving buyers official documentation that aligns with tender requirements.

This flexibility allows contractors to secure competitive advantages during bidding processes in regions such as Russia, Nigeria, and South Africa, where local authorities or insurance companies may demand proof of ballistic resistance tailored to the specific project.

6. Installation & Maintenance

The performance of a bulletproof door is only as reliable as its installation and long-term upkeep. Even doors tested to the highest ballistic standards can fail in real scenarios if installed or maintained incorrectly. For contractors and end users, understanding proper procedures ensures both compliance and security.

Installation Process

Professional Installation Teams

Bulletproof doors are heavy and structurally complex. They must be installed by certified teams familiar with ballistic resistant doors. Improper leveling or anchoring can compromise resistance performance.

Site Reinforcement and Anchoring

Frames must be anchored to structural concrete or reinforced masonry with pre-embedded steel plates or expansion bolts. In a 2023 YK Door Industry project in Germany, contractors used pre-embedded anchor plates to secure double-leaf UL 752 Level 8 armored security doors in a government facility. This ensured seamless alignment and immediate approval during compliance inspection.

Pre-Embedded Components

Many projects require pre-embedded anchor frames during the construction phase. In the Middle East, a YK installation at a bank headquarters in Dubai included integrated armored frames with interlocking anti-breach profiles. This minimized on-site welding and accelerated the installation timeline, meeting the bank’s strict construction schedule.

Maintenance Guidelines

Locking Systems

Locks and access control devices must be inspected quarterly. Electronic and biometric locks require firmware updates and periodic stress testing. Mechanical locks need lubrication to prevent jamming.

Seals and Gaskets

Ballistic doors often integrate intumescent and airtight seals. These seals degrade under heat, dust, or humidity and should be replaced every 2–3 years. In YK’s European projects, hospitals routinely request gasket replacement as part of scheduled facility maintenance.

Protective Coatings

Powder-coated steel and stainless-steel surfaces must be checked annually for corrosion, especially in coastal or desert regions. In a 2022 project for a Middle Eastern embassy, YK supplied 316-grade stainless steel bulletproof doors with anti-corrosion finishes, which required only light annual cleaning despite high humidity and sand exposure.

Hardware and Hinges

High-frequency hinges and closers must be inspected for alignment and fatigue. Replacement intervals are typically every 5–7 years, depending on usage intensity.

YK Door Industry Value

As an experienced bulletproof door supplier, YK Door Industry not only delivers certified products but also provides installation supervision and maintenance training. Our teams in Europe and the Middle East have demonstrated that proper anchoring, certification-compliant installation, and preventive maintenance reduce the risk of inspection rejection and extend service life. By combining technical support with certified documentation, YK ensures that armored security doors remain fully compliant and operational for decades.

7. Why Choose Us / Benefits

Choosing the right partner for bulletproof doors is not only a matter of certification but also of trust, flexibility, and proven experience. YK Door Industry delivers more than products; we provide complete security solutions tailored to each client’s needs.

Customization Capabilities

Every project demands unique specifications. At YK, we design armored security doors that can be fully customized in size, finish, and function. Whether it is an oversized ballistic resistant door for an embassy compound, or a discreet wood-veneered bulletproof door for a private residence, our engineers ensure compliance with EN, UL, NIJ, and ABNT standards without compromising architectural design. Advanced features such as biometric locks, electromagnetic closers, or acoustic insulation can be integrated on request.

Delivery and After-Sales Assurance

Time and reliability are critical in high-security projects. As a manufacturer-direct supplier, YK controls every stage from material sourcing to final assembly. This allows us to commit to predictable delivery schedules and minimize project delays. Our after-sales program includes installation training, maintenance guidelines, and spare parts supply, ensuring that doors remain fully operational throughout their service life. In international markets, our local partners receive continuous technical support, guaranteeing smooth handovers and long-term compliance.

Proven Global References

Our credibility is built on successful projects across multiple regions:

-

Banking Security: A major bank headquarters in Dubai equipped its cash vaults with UL 752 Level 8 bulletproof doors, delivered and installed by YK with full certification.

-

Diplomatic Missions: An embassy facility in Moscow upgraded perimeter entrances with EN FB6 armored security doors, balancing ballistic resistance with architectural aesthetics.

-

Private Sector: Luxury villas in South Africa’s gated communities now feature wood-finished ballistic resistant doors, offering discreet protection to high-profile residents.

Each project demonstrates our ability to adapt to local regulations, deliver on time, and provide documentation that satisfies both government inspectors and insurance auditors.

Manufacturer-Direct Advantage

As a reliable bulletproof door manufacturer, YK Door Industry eliminates middlemen, ensuring competitive pricing, transparent communication, and strict quality control. Our factory-direct model guarantees that clients receive not only certified bulletproof doors but also the technical expertise and customization flexibility that distributors cannot provide.

Conclusion & Call to Action

The global demand for bulletproof doors continues to rise as governments, banks, developers, and private clients place greater emphasis on resilience and security. From armored security doors in financial vaults to ballistic resistant doors in embassies and critical infrastructure, the choice of supplier determines not only compliance but also long-term safety.

YK Door Industry has proven expertise as a reliable bulletproof door manufacturer, delivering certified products that meet EN, UL, NIJ, and ABNT standards. Our commitment to customization, timely delivery, and after-sales support ensures that every project benefits from doors designed to perform under real-world conditions.

Whether you are a contractor bidding on a government tender, a bank upgrading its security systems, or a developer building private estates, our team can provide tailored solutions backed by laboratory ballistic testing and complete certification packages.

👉 Contact YK Door Industry today to discuss your security project. Together, we can deliver bulletproof doors that combine uncompromising protection, global certification, and architectural flexibility.

Reviews

There are no reviews yet.