Structural Features of UL Fire Doors: A Technical Insight by YK Fire Door Supplier

As a leading fire door manufacturer, YK Fire Door Supplier is committed to delivering high-performance solutions that meet international standards. Among the most critical safety components in commercial and residential buildings are UL steel fire doors, which are meticulously designed to resist fire and smoke penetration during emergencies. This article explores the key structural features that define the reliability and durability of UL certified fire doors.This article and the related internal links can help you gain a detailed understanding of the structure of a UL fire door.

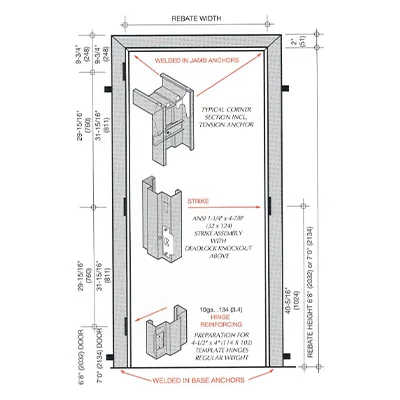

1. Reinforced Fire Door Frames for Enhanced Integrity

The fire rated door frame is a crucial structural component that ensures the door assembly can resist fire over its rated period. At YK, our UL certified fire door frames are crafted from galvanized or cold-rolled steel sheets, typically 1.6 mm thick, ensuring both mechanical strength and heat resistance. Internally, the frame is often filled with mineral wool or other fire retardant materials to bolster the unit’s thermal insulation performance.

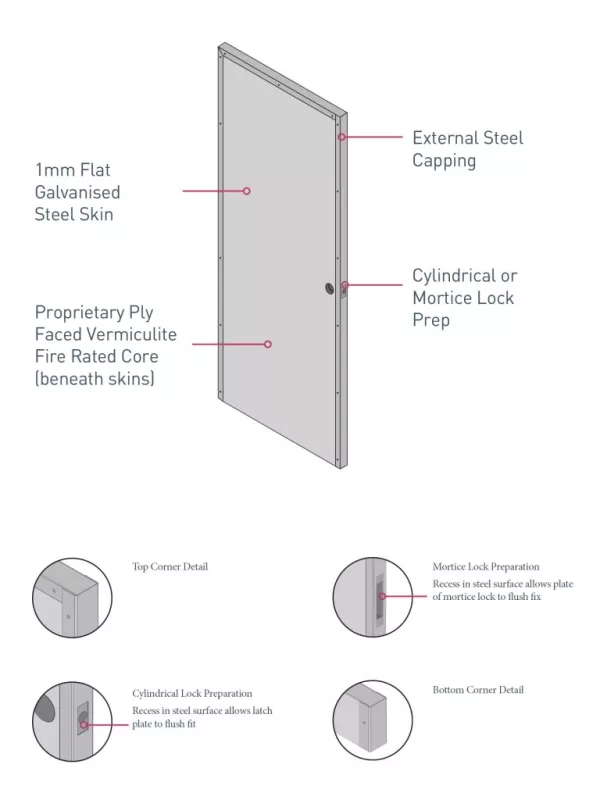

2. Multi-Layered Fire Rated Door Leaves

The door leaf of a UL listed fire door is a composite of advanced fire resistant materials. YK designs incorporate a steel sheet outer shell (1.2 mm thick) filled with treated rock wool insulation, ensuring excellent thermal retention and structural endurance. In many configurations, we also integrate UL listed fire-rated glass—such as the 5 mm Keralite FR glass from Saint-Gobain—to offer visibility without compromising fire containment.

This layered structure maintains the door’s ability to endure high temperatures and physical stress, effectively isolating fire and smoke from spreading to adjacent areas.

3. Certified Fireproof Sealing Technology

To prevent the leakage of smoke and hot gases, UL fire resistance doors from YK are equipped with intumescent seals and high-temperature silicone gaskets installed along door edges and frame gaps. These seals expand when exposed to heat, forming a barrier that restricts fire spread. Their elasticity ensures a snug fit between the frame and door leaf, maintaining airtight closure during critical situations.

4. Fire Door Locks and Closers Built for Emergencies

At YK, each fire door lockset is engineered to function under high-temperature stress. These locking systems are UL tested, ensuring safe and reliable operation even during intense heat exposure. Furthermore, our doors include fire door closers that guarantee self-closing action as per UL 10C standards—an essential feature in maintaining compartmentalization during a fire event.

UL fire-rated door handles, latches, door closers, and bolts

5. Mandatory Certification Labels and Markings

Compliance and traceability are non-negotiable in fire protection systems. All YK UL fire doors are visibly labeled with fire ratings, certification bodies (e.g., UL), and model specifications. These labels, whether printed, engraved, or stickered, validate the door’s performance under UL 10B/UL 10C and NFPA fire testing protocols.

Such markings are essential not only for compliance but also for on-site verification during inspections or audits.

CE Fire Door Ratings vs UL Ratings: Understanding the Difference

| Parameter | UL Certification | CE Certification | YK Dual-Compliance Strategy |

|---|---|---|---|

| Testing Temperature | ASTM E119 curve (rapid rise) | EN 1363-1 curve (gradual) | Core materials validated under both curves |

| Sprinkler Assumption | Mandatory | Optional | Reinforced edge seals for non-sprinkler EU builds |

| Labeling Requirements | Permanent UL label | CE + UKCA marks | Laser-etched dual markings on door edge |

While UL fire door ratings are primarily recognized in the Americas and Middle East, CE fire door ratings are required for conformity across Europe. YK Fire Door Supplier manufactures both UL and CE compliant doors, understanding that both systems, though different in test methods, aim to ensure that fire resistant doors perform as life-saving barriers in emergency scenarios.structure of UL fire door.

CE-rated doors are tested under EN standards such as EN 1634, and unlike UL standards, they often include additional criteria like thermal insulation (EI) and integrity (E) ratings. YK’s ability to meet both ensures our global clients receive regionally appropriate and fully certified products.

UL Fire Door Specification Overview–structure of UL fire door

Here are standard technical specifications of YK’s UL listed fire rated doors:

- Fire Rating: 120 minutes UL listed

- Door Frame: Galvanized steel, 1.6 mm thick, double rebated

- Leaf Thickness: 45 mm–49 mm

- Infill Material: Treated wool insulation

- Glass: UL listed 5 mm Keralite FR

- Finishes: Powder-coated (custom RAL codes), optional wood grain

- Configurations:

- Single Leaf: 1300 mm × 2500 mm

- Double Leaf: 2000 mm × 2400 mm

All configurations are rigorously tested for structural integrity, smoke control, and flame containment, aligning with the latest fire safety door regulations under UL and IBC codes.

Conclusion: Why Choose YK Fire Door Supplier?

YK Fire Door Supplier is not just a fire rated door manufacturer—we are innovators in passive fire protection. Our UL fire doors combine structural strength, thermal insulation, and smoke control technologies to provide comprehensive safety. Whether your project is in North America, Europe, the Middle East, or Southeast Asia, we offer fully certified UL and CE fire door systems tailored to your local compliance needs.

Investing in high-quality fire resistance doors means protecting lives and assets. At YK, we make that protection reliable, tested, and globally compliant.

Pingback: UL Certification for Fire Doors - YK | Fire Doors | Fire Windows | Fire Shutters

Pingback: UL fire door price - YK | Fire Doors | Fire Windows | Fire Shutters

Pingback: Top 10 NFPA Fire Rated Door Suppliers - YK | Fire Doors | Fire Windows | Fire Shutters

Pingback: Fire Door Hinges——How Many Are Needed on Fire Doors? - YK | Fire Doors | Fire Windows | Fire Shutters

Pingback: Common Misconceptions about Fire Door - YK | Fire Doors | Fire Windows | Fire Shutters

Pingback: Lessons from the 2025 Fall River Fire: Why Massachusetts Is Tightening Fire Rated Door Regulations - YK | Fire Doors | Fire Windows | Fire Shutters