I’m writing this not to sell you something, but to share a piece of practical advice I’ve learned after more than a decade in the fire door industry. If you have ever tried to source fire-rated doors from abroad—especially from China—you already know how confusing the market can be. Some companies claim to be “manufacturers” but actually work from rented office space. Some use borrowed factory photos. Some outsource everything and have no control over quality or delivery.

So here is the simplest, fastest, and most reliable way to know whether the supplier you’re talking to is a real fire door factory or just a trading company:

Video call the owner.

Not a sales representative.

Not a customer service agent.

The actual owner.

Because if a company truly has its own production line, its own machines, its own workers, and real day-to-day operations, the owner can walk into the workshop with a phone—any time you ask. There’s no need for scheduling, staging, or rehearsing. A real factory doesn’t need to prepare. It just exists, every minute of every working day.

And I’m sharing this because I want buyers—whether contractors, distributors, builders, architects, or project managers—to feel more confident and less worried when choosing a fire door supplier. I’ve seen too many people lose time, money, and trust simply because they didn’t know how to verify the manufacturer behind the email signature.

This is not a marketing trick.

This is a method.

A method that works.

You don’t need to be an expert.

You don’t need to understand production techniques.

You just need to ask the owner to turn on the camera.

What you see will tell you everything.

Why It’s Important to Confirm Whether You’re Dealing With a Real Fire Door Factory

I’ve spoken with many overseas clients who told me the same story: they thought they were working with a factory, only to find out later that the company was actually a trading office with no production capability. I want to make this very clear — there is nothing wrong with trading companies. Some of them offer good communication and service. But when you are sourcing fire-rated doors for real projects, the stakes are different.

Fire doors are not ordinary commercial products. They are safety equipment.

If something goes wrong — the door warps, the core is incorrect, the hardware fails — it is not just a matter of product return or warranty dispute. It affects:

- Project inspection and approval

- Delivery timeline and contractor scheduling

- Building safety compliance

- Your reputation with your clients

When the supplier who promised production control actually has no factory, they cannot control quality, cannot respond quickly, and cannot solve problems at the manufacturing level. All they can do is “ask someone else.” And every extra layer between you and the workshop means more uncertainty.

That’s why I encourage people to verify the real production background of their fire door supplier.

Not to reject trading companies, but to give yourself a better option:

If you can find a fire door factory that offers the same responsiveness, the same communication efficiency, and the same attention to detail — while also having real on-site production — then choosing the factory simply makes more sense.

It saves money, reduces risk, and gives you direct control.

And the easiest way to verify that?

A video call.

No documents, no brochures, no edited photos — just reality, in real time, inside the workshop.

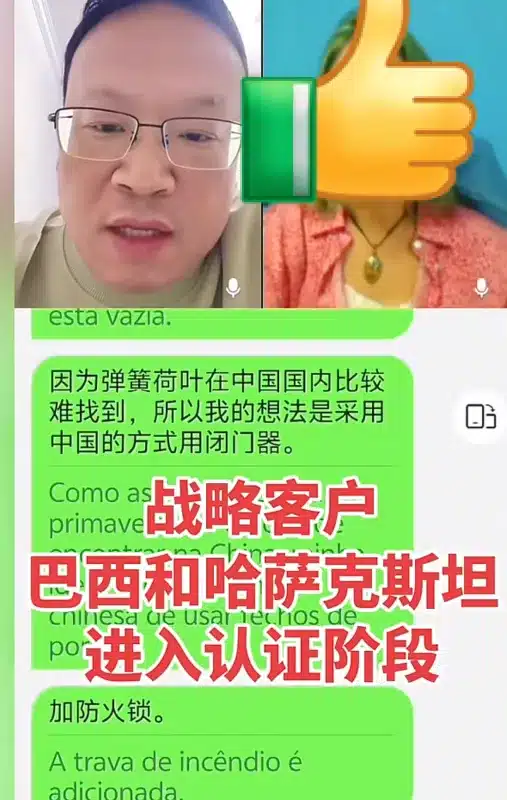

Video Calling Is the Most Direct and Practical Way to Verify a Factory

I always tell customers this: if you want to know whether a factory is real, don’t look at pictures first. Photos can be borrowed. Workshops can be staged. A certificate can be scanned and forwarded. Even a company registration number doesn’t tell you whether the company actually produces anything. In this industry, it’s not difficult for someone to make themselves look bigger than they really are.But a video call is different.Video is immediate.Video is transparent.Video leaves no room for rehearsing.

When you video call me, I don’t need to prepare a showroom. I don’t need to organize workers to stand in perfect formation. I simply pick up the phone and walk straight to the production floor. You will hear the sound of the cutting machine, the rhythm of the punch press, the welding sparks, and the roller of the coating line. These things are hard to fake because they happen in motion — not in decoration.And more importantly, a real fire door factory cannot be moved.You can borrow someone else’s photos.But you cannot borrow someone else’s workers, or their machines, or the flow of real production happening in front of the camera.

When I start a video call with a customer, I don’t guide the camera only to the “pretty places.” I show the entire process — the raw steel sheets before cutting, the frame bending, the fire-resistant core filling, the screw fixing points, the intumescent seals being applied, and finally the packaging area where finished doors are stacked and ready to ship. It’s not glamorous, and it’s not quiet. But it is real.

And reality builds trust.

A real fire door manufacturer does not fear showing the workshop. We live inside the noise, the metal dust, the smell of paint curing in the drying room. These are not things you can Photoshop. These are the true signals of production.

So when I say, “Just video call me anytime,” I mean it.

Even if you call when I am outside or on the road, give me thirty minutes — I will be in the factory. Not because I need to perform, but because I am here every day. I am involved. I am responsible. And as the owner, I have nothing to hide.

In this world, trust does not come from a brochure.

It comes from what you can see happening right now, in real time.

That is why a simple video call is worth more than any certificate, catalog, or sales pitch.

How I Personally Guide Customers Through the Factory During a Video Call

When a customer requests a video call, I don’t arrange a “factory tour schedule” or ask anyone to tidy up before filming. I simply take the phone, say “Let’s go,” and walk straight to the workshop. The truth of a factory is not in the prepared presentation. It’s in the ordinary working moment — the moment when no one expected a camera.

There is a kind of honesty in the everyday noise of production.

You hear machines stamping.

You hear sparks crackling during welding.

Sometimes a worker jokes with another across the table.

Sometimes the equipment gives a low vibration hum that fills the space like a heartbeat.

These sounds are proof. They tell you the factory is alive.

When I start the call, I usually begin at the raw material area. I show the cold-rolled steel sheets stacked on pallets, the thickness markings still visible. This is where every fire door begins — not at a “display showroom,” but right here on the concrete floor where the inventory is tracked and scheduled.

Then I walk toward the cutting and bending machines.

You will see the operators, gloves worn smooth from repetition, guiding each sheet into the bending press. Their movements are practiced, not rehearsed for the camera. They know their craft, and you can feel it — not from what I say, but from how they move.

Next, I show the welders at work. Sparks fly. The air is warm. The camera sometimes catches a flare of light. It’s not elegant, but it’s exactly how fire door frames are shaped and reinforced. This is the kind of detail you simply cannot explain through brochures or photos.

From there, I move to the core-filling and assembly section. The fire-resistant core material, the intumescent strips, the hinge reinforcement — everything is visible, piece by piece. If you want, I will stop, open a semi-finished door panel, and show you how the core is distributed inside. I encourage customers to ask questions during the call. The more specific your questions, the clearer the answer — because my answers come from what is literally in my hand at that moment.

Finally, I show the spray coating line and the packaging area. You will see finished fire doors lined in rows, labeled, wrapped, and waiting for shipment — each one with a destination. Some are going to schools. Some to hospitals. Some to hotels. Some to residential buildings. These doors will protect real people. That matters.

What I want customers to feel is not “impressed.”

What I want is for you to know — with certainty — where your product comes from, who makes it, and how seriously we take it.

Video is not about performance.

It’s about presence.

And when I guide you through the workshop, what you’re seeing is my daily life — not a staged exhibition.

I think this is the most honest form of communication a factory can offer.

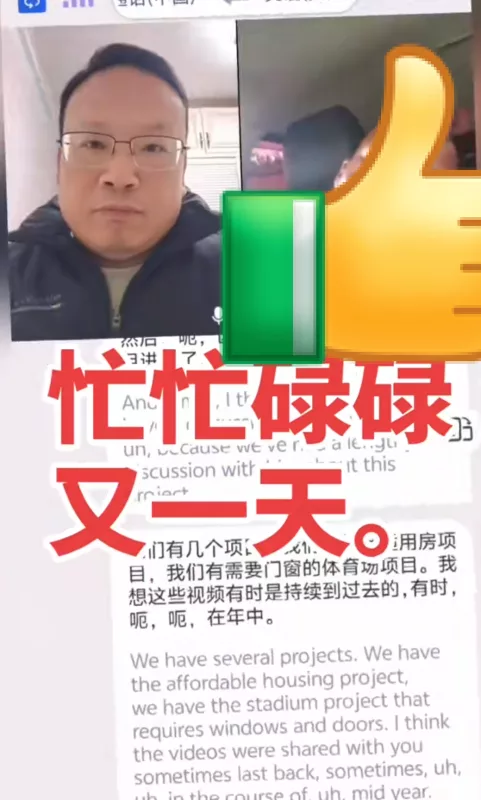

Why I, as the Factory Owner, Personally Work With Overseas Clients

People sometimes ask me, “Why is the owner the one answering messages, making calls, and walking through the workshop camera in hand? Don’t you have salespeople for that?”

Of course we have a domestic sales team. And we have distributors inside China who have worked with us for years. The domestic market is stable. We have already built trust and reputation there. Our customers know our production standards and they know what to expect from us. The foundation is solid.

But the international market is different.

Every overseas customer is placing a bet — on quality, on schedule, on communication, on responsibility. And I respect that bet. I know what it means to send money across continents and trust that the goods will arrive exactly as promised.

That is why I handle overseas clients personally.

I am not just a “factory owner.” I am also our head salesperson, technical decision-maker, and problem-solver. If you message me, you are speaking directly to the person who:

- Can set the price

- Can adjust the structure or material based on your project needs

- Can approve urgent production scheduling

- Can arrange new samples without delay

- Can decide yes or no instantly

There is no, “Let me check with my boss.”

I am the boss.

And when the decision is mine to make, communication becomes clean and quick.

You ask → I answer.

You request → I execute.

You have a concern → I solve it at the production floor level, not through layers of office replies.

“即时决策、即时确认、即时推进” is not a slogan for us.

It is how we survive in a market where the only companies that last are the ones who respond fast and deliver reliably.

This is not about being “important.”

It’s about being responsible.

When you are the one who stands inside a real fire door factory every day—walking the production floor, watching each door take shape—you understand that every decision affects safety, timelines, and people who will one day rely on that door to protect their lives. Responsibility is not a slogan here. It’s the air we work in.

Fire doors are project products.

They are almost always tied to schedules, inspections, and safety approvals.

A one-day delay may mean subcontractors waiting idle, construction timelines shifting, or inspection windows closing.

When you work directly with the person who controls production, you avoid all of that.

And I want my overseas customers to feel something very specific when they work with me:

You are not negotiating with a salesperson who has limits.

You are building a working relationship with the person who will personally ensure your order is correct, on time, and backed by real accountability.

This is not about being “important.”

It’s about being responsible.

I believe if I ask you to trust my factory, then I should be willing to stand in front of the camera, walk into the workshop, look you in the eye, and say:

“This is who we are.

This is how we work.

And I will take responsibility for everything we produce.”

That is the real meaning of trust in international business.

In Today’s Market, High Quality and Reasonable Pricing Must Coexist

The fire door industry is going through a quiet reshuffling. Companies that relied on low-cost shortcuts are disappearing one after another. It’s not luck. It’s simply that the market no longer tolerates products that look fine in photos but fail when they face real project inspections. In this environment, only a real fire door factory—one that controls its own production, materials, and quality from start to finish—can consistently meet the standards that buildings and human lives depend on.

A fire door is not a decorative panel.

It either performs in heat and smoke — or it doesn’t.

There is no middle ground.

Over the years, I have seen two types of customers most clearly:

- Those who have experience, and therefore know exactly what they are looking for.

- Those who learn through mistakes, often because the first supplier they trusted did not actually control production.

I’ve worked with clients in Kenya who needed high-security and fire-rated ballistic steel doors for government and infrastructure sites. In projects like those, “almost good enough” is simply not acceptable. The door structure must hold. The steel composition must be correct. The internal reinforcement must be continuous. If any part is compromised, the entire door loses meaning. And when the client sees the welding pattern and reinforcement ribs during a video call, they immediately understand the value of real manufacturing capability.

On the other hand, I’ve also worked with clients in several European markets where building codes are practical rather than over-restrictive. For many applications — residential corridors, warehouse partitions, small commercial spaces — standard Chinese 3C-certified fire doors are already compliant, affordable, and easy to install. In these cases, what the customer needs is not “the highest possible specification,” but stable quality with a reasonable price, delivered on time, without complications. And that is precisely where a real factory makes the biggest difference.

So the idea that “high quality equals high cost” is not accurate anymore.

The real formula today is:

Correct quality for the correct application + transparent pricing + controlled production = long-term cooperation.

This is why I often say:

In this market, those who survive are not the cheapest, nor the loudest.

They are the ones who can guarantee both performance and affordability — continuously.

And that is exactly where factories and trading companies differ in long-term advantage:

- A trading company can adjust communication style.

- But only a factory can adjust material selection, process sequence, reinforcement method, coating system, delivery scheduling — the parts that actually matter.

Every overseas customer deserves options — not just quotations.

So whether you are sourcing ballistic steel doors for Nairobi, or 3C-rated fire doors for a mid-size European residential project, the key is the same:

See the factory.

Watch the process.

Let the product speak for itself.

Not through brochures —

but through reality, in a video call, in motion, in the workshop where the door is born.

Choosing a Supplier Has Never Been About Who Talks the Best

I know that sourcing decisions are not easy.

There are budgets, deadlines, regulations, and sometimes pressure from many sides.

And when you’re dealing across borders, trust becomes even more fragile — and more valuable.

So I don’t expect anyone to believe me just because I say I’m a manufacturer.

I don’t expect anyone to trust me just because I speak confidently.

And I certainly don’t expect you to choose us simply because you’ve read these words.

Trust is not built by persuasion.

It’s built by what you can see and confirm for yourself.

That is why I always offer the same simple request:

Just call me.

No schedule. No preparation. No performance.

If you want, I will walk with you through every corner of our factory — slowly, patiently — the same way I walk it every day.

You will see the machines that age with us.

The people who work with both hands and memory.

The doors that move from raw steel to finished protection.

The quiet confidence of a place that knows its purpose.

Whether your project is in Nairobi, or Warsaw, or Athens, or a small coastal town where the air smells of salt — I want you to feel that your supplier is not far away. That there is a real person here, with real responsibility, who will answer when you call.

I am not trying to prove that we are the best.

That is for time to decide.

All I want is for you to know that on the other side of the screen, there is someone who works with honesty, steadiness, and respect for the trust others place in him.

My name is Zheng Chunjie.

If one day you want to see our factory,

just call — and I will walk you in.