If you walk through an older factory or a mid-century warehouse, you’ll often find the kind of fire doors that defined safety practices in the 20th century—solid slabs of steel or thick timber, heavy to push and louder than you’d expect when they close. These doors were designed with a single purpose: to hold back flames long enough for people to escape. They didn’t need to fit into the building’s interior style, and no one was thinking about energy efficiency, smoke control, or how doors interacted with alarms or ventilation systems. Fire safety at that time was mostly physical and mechanical.

By contrast, fire doors in the 21st century reflect a completely different relationship between buildings and safety. Modern fire door technology is not just about resisting heat. It’s about containing smoke, maintaining visibility, controlling movement through hallways, and fitting seamlessly into residential, commercial, and public architectural environments. A modern fire-rated door might look like a glass wall in a hospital corridor or a sleek panel in an office lobby. The safety function is still there, but it no longer has to interrupt the design of the space. That shift tells us a lot about how expectations around fire safety have evolved with changes in construction materials, digital systems, and building regulations.

This transition didn’t happen overnight. It came from decades of building fires, new scientific understanding of smoke spread, and the gradual movement from industrial-age construction to dense urban living and multi-use buildings. As cities grew upward and inward, fire doors had to adapt. The 21st century brought new testing standards, new composite cores, and intumescent seals that swell to block smoke—a quiet but crucial development in modern fire door performance. And today, in many buildings, fire doors are connected into electronic life-safety systems that can automatically close or unlock depending on emergency signals.

Understanding these changes helps explain why 21st-century fire doors look, feel, and function so differently from those of the past. It’s not just better materials; it’s an entirely different safety philosophy.

Materials — From Heavy Industrial Steel to Lightweight Multi-Layer Composites

In many buildings constructed during the mid to late 20th century, fire doors were typically made from solid wood or sheets of cold-rolled steel. The logic was practical: use dense, simple materials that could slow down flames long enough for evacuation. These doors were sturdy and predictable, but anyone who has tried to push one closed in an old warehouse knows the downside—they were heavy, difficult to maneuver, and not particularly effective at controlling heat transfer. Once the surface was exposed to high temperatures, heat conducted quickly through the metal, and smoke could still move through gaps.

The shift in the 21st century was not sudden, but it was significant. As building environments diversified—from hospitals with transparent hallways to residential towers requiring better comfort control—fire doors had to do more than hold back fire. They needed improved insulation, enhanced structural stability, and internal layers that respond to heat intelligently. This is where multi-layer composite cores began to play a defining role. A typical modern fire door may combine galvanized steel sheets, fire-rated wood veneers, magnesium oxide boards, and insulating core materials that slow heat transmission rather than simply resisting it on the surface.

A clear comparison can be seen in hospitals and educational buildings. In a 1970s school, a fire door might have looked like a plain metal slab—functional but visually intrusive. In a 21st-century school renovation, the same required fire rating may be achieved with a door that incorporates fire-resistant glass panels, allowing natural light into hallways while still containing heat and smoke. The performance is not just about resisting flame anymore; it’s about preserving safe visibility and psychological calm during an emergency, especially in public spaces.

Another example is residential corridors. Older apartment buildings often relied on solid wooden fire doors that could char on the surface and lose structural integrity when exposed to sustained heat. Modern residential fire doors now often feature intumescent sealing layers that expand under temperature changes, forming a tighter barrier that limits both flame and smoke spread. This is especially important because smoke inhalation, rather than flame contact, accounts for the majority of fire-related fatalities.

What’s different between the two eras is not only what the doors are made of, but the way the materials are arranged and expected to perform. 21st-century fire doors are lighter yet more fire-resistant, relying on engineered layering instead of sheer mass. This approach requires more precise manufacturing and standardized fire testing, but it also results in doors that integrate more comfortably into varied architectural styles—from minimal modern interiors to glass-forward commercial spaces.

In short, the material story of fire doors mirrors the evolution of building culture itself: moving from heavy industrial durability toward thoughtful, layered protection that balances performance, safety, and everyday use.

Fire Performance — From Basic Flame Blocking to Heat & Smoke Control

For much of the 20th century, the performance of a fire door was judged almost entirely by how long it could stand up to direct flame. If it could stay in place for thirty or sixty minutes, the door was considered successful. Heat transfer, smoke seepage, and air pressure movement inside buildings were not yet widely understood as part of fire dynamics. That is why older fire doors often did their job structurally—but still allowed smoke to migrate through hallways, stairwells, or ventilation gaps. And in most fire events, smoke becomes the first and greatest danger. It moves faster than flames, fills escape routes, and disorients people within seconds.

The 21st century brought a different understanding of what “fire performance” actually means. Modern fire-rated door systems are designed not only to resist flame but to control smoke movement, slow heat conduction, and preserve breathable airspace long enough for organized evacuation. Many modern fire doors incorporate intumescent seals—materials that expand when exposed to high temperature. When heated, these seals swell into the small clearance gaps around the door, forming a tighter barrier. It’s a quiet detail, but it changes everything: corridors stay clearer longer; stairwells remain navigable; and fire crews have more minutes to locate and assist people inside the building.

This shift—from blocking fire to managing smoke—is one of the most defining differences between 20th-century and 21st-century fire door technology.

Understanding Smoke as a Primary Threat

Smoke behaves differently than fire. It is lighter, faster, and capable of passing through cracks no wider than a credit card. In high-rise and multi-use buildings, smoke can rise through elevator shafts, circulate through HVAC systems, and fill stairwells long before visible flames appear. This is why modern building codes increasingly emphasize smoke control performance.

In a modern apartment corridor, for example, a fire door may remain visually “unchanged” during a fire event, yet the most important action is happening in the seal around the door. The expansion of the intumescent layer slows smoke spread, giving residents precious extra time. It is a performance characteristic that cannot be seen in everyday use—but it matters profoundly in emergencies.

Positive Pressure Testing Changed the Door Industry

Older fire testing methods focused on flame exposure without simulating the pressure conditions that push smoke through openings. Today, many regions use positive pressure fire testing (such as UL 10C in the U.S.), which replicates how smoke and heat actually move upward and forward during a real fire.

This change led manufacturers to redesign not only the door leaf, but also the frame profile, hinge reinforcement, and sealing continuity. In other words, the fire door became a system, not just a slab.

Performance That Safeguards Movement and Visibility

In hospitals, airports, and educational buildings, evacuation relies on visibility and calm movement, not just blocked flames. This is why 21st-century fire doors increasingly use fire-rated glass. The glass does not replace safety requirements; it complements them by maintaining sightlines. A clear corridor reduces panic. A nurse can check a patient room without opening the door. A firefighter can assess conditions before entering.

Defense is no longer about sealing people away from danger—it’s about letting them move intelligently away from it.

Design Philosophy — From Industrial Utility to Architectural Integration

In the 20th century, fire doors were mostly treated as industrial equipment. They appeared in factories, storage hangars, boiler rooms, and service corridors—places where aesthetics were not a concern and safety was understood in strictly functional terms. A fire door was something you noticed when you passed it, because it usually looked different from everything around it: heavier, darker, louder, and separate from the visual language of the building.

The 21st century shifted expectations. As buildings became more open, transparent, and mixed-use, fire doors needed to contribute to the environment rather than interrupt it. Hospitals rely on natural light to support patient recovery. Hotels and residential buildings use visual continuity to create a sense of comfort. Office interiors increasingly prioritize visual openness for collaboration. In these spaces, a solid industrial steel slab would feel out of place—even if it met the technical safety requirements.

This is where fire-rated glass doors and composite fire door assemblies became deeply integrated into architectural planning. Instead of hiding fire protection behind heavy hardware, building designers began working with door systems that could provide a continuous visual line while still maintaining certified fire resistance and smoke control.

A practical example can be seen in recent public health buildings in China. In several hospital renovation projects, Yuankai Door Industry was asked to supply fire-rated doors that did not visually dominate corridors or patient care areas. In one children’s medical center, the design team selected steel-framed fire doors with narrow fire-resistant glass panels. The transparent portions maintain visibility across long hallways—a key factor for staff response and patient safety—while the door cores and intumescent seals still meet the required fire endurance rating.

In a university research building completed two years later, the project goals were slightly different. The architects wanted a warmer, less clinical atmosphere in shared study areas. For this, Yuankai supplied wood-veneer fire doors with concealed core reinforcement. The structural performance was there—but the doors read visually as part of the interior design rather than as emergency hardware. Students and staff likely walk past these doors every day without thinking about their fire rating. That is, in itself, a sign of successful architectural integration.

This change in design philosophy is not simply about “making safety equipment look nicer.” It reflects a broader recognition that people move, perceive, and respond differently in emergencies when environments feel familiar and navigable. When a building allows visibility, consistent sightlines, and intuitive flow, evacuation can be calmer and more efficient. The fire door becomes not just a barrier, but a participant in how safety and daily use coexist.

In other words, 21st-century fire doors are as much about human experience as they are about fire science. They are expected to work quietly in the background—strong when needed, unobtrusive when not.

Standards and Certification — Regulations Became More Precise and Multidimensional

Standards for fire doors used to be relatively straightforward. In the 20th century, many building codes focused mainly on how long a door could resist direct flame exposure—commonly thirty, sixty, or ninety minutes. The testing environments were controlled but simplified, and evaluation criteria usually centered on structural endurance: Does the door stay in place long enough for evacuation? If the answer was yes, the door passed.

But as research into fire behavior progressed, it became clear that a door holding its shape was not enough. Smoke leakage, temperature transfer through the core, and frame distortion under pressure all influence whether a hallway or stairwell remains usable during a fire. A door that withstands flames but leaks smoke can still render an escape route unusable. These findings reshaped global fire door standards.

By the early 21st century, testing procedures had evolved into multidimensional certification. Standards such as UL 10C in the United States began applying positive pressure conditions to simulate real fire scenarios, where heated air and smoke push forward and upward. In Europe, EN 1634-1 introduced integrated assessments that evaluate not only flame resistance but also temperature rise, smoke control, and hardware stability. The UK’s BS 476 and China’s GB 12955 / 3C certification system similarly expanded the criteria to include frame performance, sealing continuity, and door leaf deformation.

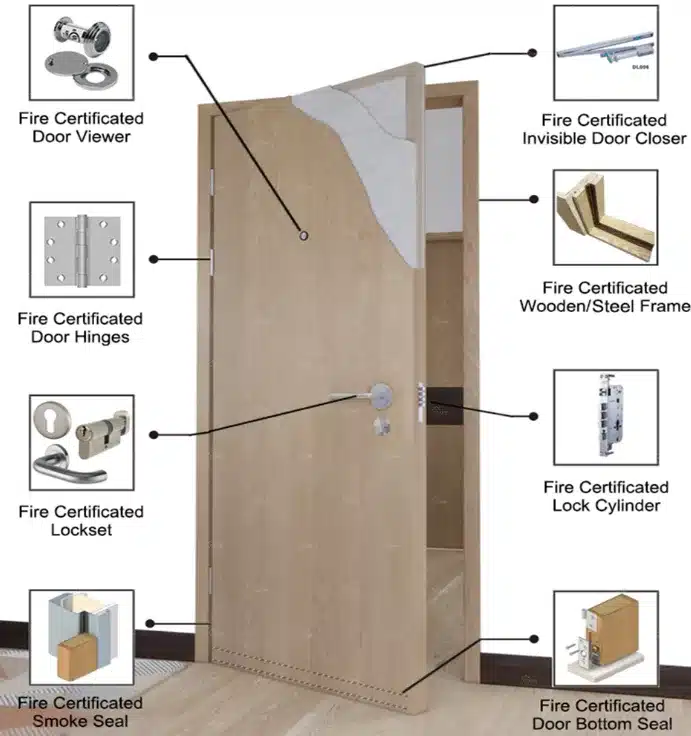

For manufacturers, this changed how doors were engineered. Instead of relying solely on mass and density, modern fire doors require precise material layering, tested sealing systems, and hardware compatibility that can maintain alignment under thermal stress. It is not enough for each component to perform independently—the entire door assembly (leaf, frame, hinges, closer, seals, glazing, locks) must perform as a single system during testing.

In practical terms, this means a fire door today is not just a product; it is the result of coordinated design decisions. The standards require proof, not assumption. Performance must be demonstrated through full-scale burn testing, rather than inferred from material properties.

For example, in one municipal office building project, Yuankai Door Industry provided fire doors that required testing under both smoke control classification and positive pressure endurance. The architects wanted slim-profile frames for a modern, airy aesthetic, but the building code required guaranteed smoke compartmentalization. The solution involved a combination of intumescent sealing strips, reinforced hinge plates, and proper fire-rated glass spacing to ensure the door would maintain its seal in actual heat conditions. The certification process confirmed the full assembly performed as intended—not just a single component.

This approach marks a philosophical shift:

Certification today is not only about resisting fire—it is about preserving usable escape paths and protecting breathable air.

This is, in many ways, where safety moves from theory into real-life application.

Digital Integration — The Rise of Smart and Networked Fire Door Systems

For most of the 20th century, fire doors worked independently. They stayed open or closed based on mechanical hinges and door closers, and they responded only to the movement of people or the force of gravity. If a fire alarm sounded, building staff or emergency responders were often responsible for closing doors manually. Safety was functional, but it relied heavily on human action and awareness.

In the 21st century, the way buildings are managed has changed. Fire doors are increasingly connected to digital monitoring systems, central fire alarm networks, and automated evacuation protocols. Instead of acting as isolated pieces of equipment, fire doors now participate in real-time building decision-making.

In many newer hospitals, schools, and transportation hubs, doors that stay open during normal use are fitted with electromagnetic hold-open devices. When the fire detection system activates, the magnets release, and the doors close automatically. This transition happens in one motion, coordinated across hallways and stairwells, helping isolate smoke and direct evacuation flow. The result is not only faster compartmentalization—it also reduces confusion and hesitation among building occupants.

Some buildings go further, integrating access control with fire safety. Doors that require key cards during normal operations automatically unlock during a fire alarm. This prevents bottlenecking and ensures that evacuation routes remain clear. The focus is on making buildings behave intelligently during emergencies, not just structurally resisting fire.

In one cultural center project completed with the involvement of Yuankai Door Industry, the fire doors were connected to the facility’s building management system. During daily use, the doors remained open to allow smooth movement between exhibition areas. But when the fire alarm system triggers, the doors close in predefined zones, creating smoke compartments while still allowing visibility through fire-rated glass panels. Staff can move between areas through designated controlled points, and first responders can monitor the situation without forcing entry. The technology does not replace human judgment—it supports it.

This integration marks a quiet but meaningful shift. Fire doors today are not simply barriers; they are components of a coordinated safety network. They contribute to:

- Evacuation direction

- Smoke layering and pressure control

- Protection of escape stairwells and critical hallways

- Real-time situational awareness for emergency teams

The goal is no longer just to stop fire from spreading. It is to shape how people move during emergencies, preserving clarity, breathable space, and navigable routes.

Digital integration did not make fire doors more complicated—it made them more human-aligned.

Conclusion — Fire Doors as a Reflection of Evolving Safety Culture

Looking at the differences between 20th-century and 21st-century fire doors, what stands out most is not simply the change in materials or manufacturing techniques, but the shift in how societies think about safety. In earlier decades, fire protection was understood as something that happened after a problem occurred—something to slow down the fire once it had already begun. A door was a barrier, and its value was measured in minutes of resistance.

Today, the expectations are broader. Modern fire doors are designed not only to withstand flame, but to shape how spaces function before, during, and after an emergency. They maintain visibility in hospitals. They preserve calm transitions in schools and airports. They close automatically in response to alarms. They limit smoke long before flames reach the corridor. And they do these things while blending into the architecture rather than disrupting it.

This progression mirrors advances in material science, fire behavior research, building codes, and digital infrastructure—but it also reflects something more cultural:

a growing recognition that the built environment has a direct influence on how people think, move, and survive under stress.

As cities grow taller and building layouts become more interconnected, the role of fire doors continues to expand. In many ways, they are no longer just components of emergency planning. They are part of how we design comfort, circulation, daylight, privacy, and accessibility every day. Their performance remains essential in moments of crisis, but their presence shapes daily life quietly and continuously.

Whether constructed with multi-layer composite cores, framed with fire-resistant glass, or connected to smart building control systems, 21st-century fire doors embody a balance:

strength without heaviness, protection without intrusion, safety without sacrificing space.

And that balance is where modern fire safety is heading—not toward equipment that only functions in emergencies, but toward systems that support human experience at all times.