Introduction

In recent months, Henan Yuankai Door Industry Co., Ltd. has received a growing number of international inquiries for fire door systems. Among them, one inquiry stood out for its remarkable professionalism and technical depth. After several rounds of communication, the client decided not to pursue the costly UL certification and instead chose a China 3C-certified fire door solution, which offered the same level of safety assurance at a more balanced cost.

At Yuankai, our mission has always been clear — to provide every client with the most suitable fire door solution according to their project’s needs and budget. Whether the requirement is for UL- or CE-certified doors for large-scale international projects, or 3C-standard doors under the Chinese national system, we aim to deliver the best quality within the same certification level and ensure lasting safety and performance.

This article shares one of the most insightful email exchanges we’ve had with a professional overseas client. The customer raised ten highly technical questions, and we prepared detailed answers that reflect both our practical experience and engineering understanding. We hope these explanations will serve as a useful reference for real estate contractors, door distributors, and professionals across the fire safety industry who are exploring China-standard fire door solutions.

Email Content — Questions from the Client

Subject: Clarifications Required – Technical and Documentation Details for Fire Door Quotation

Dear Mr. Chunjie,

Thank you for your continued and prompt support in preparing our quotation. We appreciate your assistance and would like to request clarification on the following points at your earliest convenience.

1. Commission Payment

A contract agreement will be signed between Yunngd and IRINATECH.

Our client will establish a Letter of Credit (LC), and upon retirement of the LC, the commission payment will be immediately transferred to IRINA TECH.

2. Documentation & Drawings

Please share the following documents for our technical review:

- Manufacturer’s installation method statement and fixing detail documents.

- Sample shop drawings showing fixing details, clear openings, and elevations for single-leaf, double-leaf, and sliding doors.

3. Structural Details

- Please confirm compatibility of stainless steel fire doors when installed on concrete and sandwich panel wall types.

- Kindly advise whether any additional structural support (e.g., steel or metal frame) is required to fix the jambs for pedestrian service doors and large sliding doors.

4. Door Jamb & Frame Fixing Details

- Recommended type of fixing for different wall types (chemical anchor / expansion bolt / self-tapping screws for sandwich panels).

- Confirmation whether all necessary fasteners are included in the package.

- Availability of embedded plates or anchor inserts in the wall.

- Compatibility of jamb materials (MS / SS).

5. Air Permeability Requirement

As the doors will be installed in a food manufacturing facility, air permeability is a critical performance parameter.

6. Door Seals (Single, Double & Sliding Doors)

General:

- Are the seals installed around the full perimeter of the door leaf?

- Are the seals or sealing profiles easily replaceable?

- When the door is closed, do the rubber seals press tightly against the frame and floor to ensure an air- and smoke-tight seal?

Performance & Standards:

- What air permeability rating do the door seals achieve (e.g., EN 1026, ASTM E283)?

- Are the seals tested and certified to relevant international standards (EN, ISO, UL, BS, ASTM)?

- What is the maximum allowable leakage rate at specified pressures?

- Can the seals withstand pressure differentials in pressurized areas?

Seal Construction & Material:

- What materials are used (EPDM, silicone, neoprene, thermoplastic, etc.)?

- Are the materials resistant to chemicals, moisture, UV exposure, and temperature variations?

- What is the expected service life under normal operating conditions?

- Are the seals flame-retardant or smoke-rated (e.g., UL 94, BS 476)?

- Are the seals antibacterial or suitable for hygienic applications (e.g., hospitals, food industry)?

Design & Installation:

- Please provide the seal profile and compression requirement (in mm).

- Recommended installation method (clip-on, adhesive, or mechanical fastening).

- Ease of replacement during maintenance.

- Whether any special tools or accessories are required for installation or adjustment.

- Ability of the seal to accommodate door misalignment or warping.

Our Response and Technical Fire Door Solutions

1.Commission Payment Policy — Transparent and Reliable Cooperation

At Yunngd Door Industry, we believe in transparent and mutually beneficial partnerships. All commission payments are handled through officially signed contract agreements between Yunngd and IRINATECH, ensuring full traceability and financial security for both parties. Once the client establishes and retires the Letter of Credit (LC), the agreed commission will be immediately remitted to IRINATECH without delay. This system aligns with international trade practices and complies with both Chinese export regulations and global banking standards. Our financial operations are fully supported by state-certified commercial banks, giving our partners confidence that every transaction—from production to payment—is handled professionally, ethically, and in accordance with international norms.

2.Documentation & Drawings — Complete Technical Support for Every Project

As a leading China fire door manufacturer, Henan Yuankai Door Industry Co., Ltd. provides comprehensive documentation to support every project from design to installation. Our engineering team offers a detailed installation method statement and fixing detail drawings that strictly follow both Chinese GB standards and international norms such as UL, EN, and BS.

For each project, we deliver shop drawings that clearly illustrate openings, frame elevations, and fixing methods for single-leaf, double-leaf, and sliding fire doors. These technical documents form part of our complete fire door solution, helping architects, contractors, and site engineers achieve precise coordination, minimize installation errors, and ensure full compliance with fire safety and performance standards.

We understand that international clients require clarity and assurance. That’s why all our CAD drawings, material data sheets, and test reports are professionally prepared in English, ready for submission to consultants and inspection authorities worldwide.

3.Structural Details — Designed for Versatility and Global Construction Standards

At Yunngd Door Industry, our stainless steel fire doors are engineered for structural compatibility across various wall types, including reinforced concrete walls and sandwich panel systems. Each door system is manufactured with a customizable frame structure, ensuring reliable installation whether in heavy industrial environments or lightweight modular buildings.

For concrete walls, doors are fixed using mechanical expansion bolts or chemical anchors, achieving excellent stability and fire integrity. In sandwich panel applications—common in cleanrooms, food factories, and logistics centers—we use specialized self-tapping fasteners and reinforced steel jamb supports that prevent deformation while maintaining airtight and fire-resistant performance.

In most cases, no additional structural reinforcement is required beyond the standard metal frame and fasteners supplied with the product. However, for oversized sliding fire doors or high-pressure environments, Yunngd engineers can provide tailored structural reinforcement drawings. This flexibility allows our fire door systems to integrate smoothly into international construction standards, including UL 10C, EN 1634-1, and BS 476 Part 22.

4.Structural Details — Designed for Versatility and Global Construction Standards

At Yunngd Door Industry, our stainless steel fire doors are engineered for structural compatibility across various wall types, including reinforced concrete walls and sandwich panel systems. Each door system is manufactured with a customizable frame structure, ensuring reliable installation whether in heavy industrial environments or lightweight modular buildings.

For concrete walls, doors are fixed using mechanical expansion bolts or chemical anchors, achieving excellent stability and fire integrity. In sandwich panel applications—common in cleanrooms, food factories, and logistics centers—we use specialized self-tapping fasteners and reinforced steel jamb supports that prevent deformation while maintaining airtight and fire-resistant performance.

In most cases, no additional structural reinforcement is required beyond the standard metal frame and fasteners supplied with the product. However, for oversized sliding fire doors or high-pressure environments, Henan Yuankai Door Industry Co., Ltd. can provide tailored structural reinforcement drawings. This flexibility ensures that every fire door solution integrates smoothly into international construction standards, including UL 10C, EN 1634-1, and BS 476 Part 22, meeting the needs of global engineering projects with precision and reliability.

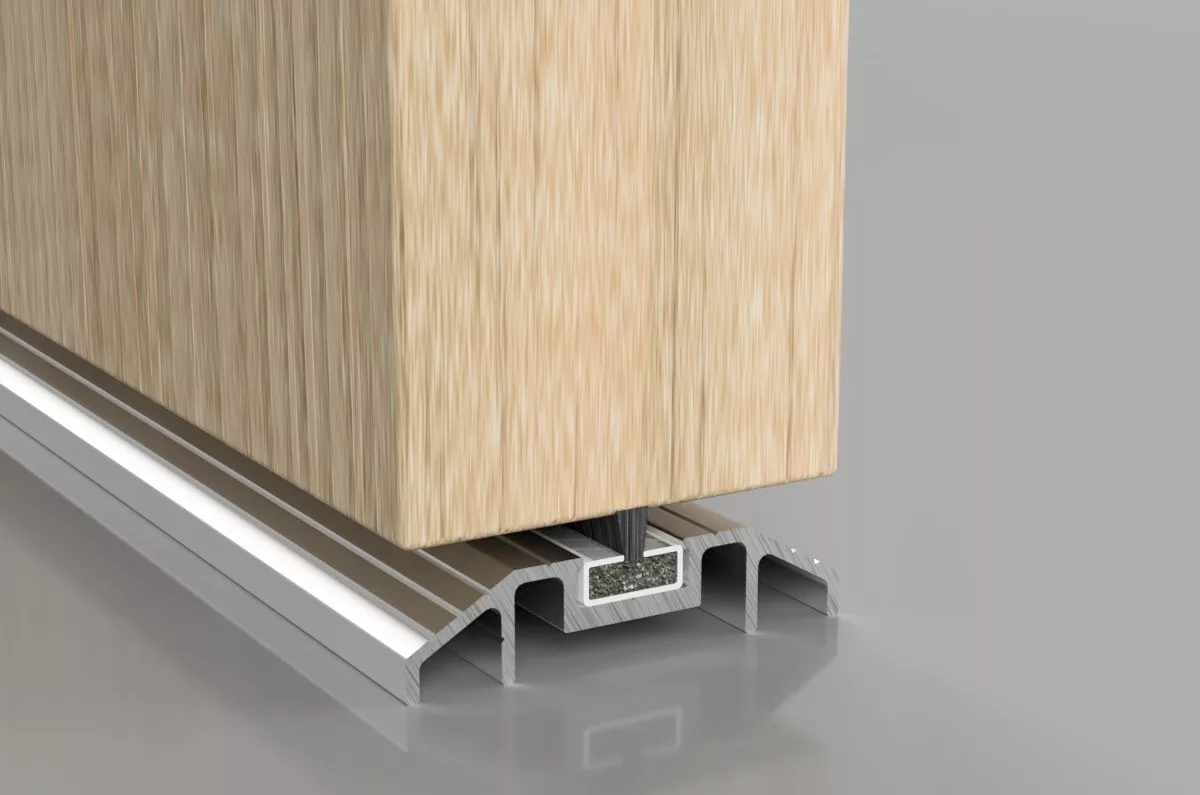

5.Door Jamb & Frame Fixing Details — Built for Stability and Practical Installation

At Henan Yuankai Door Industry Co., Ltd., every detail of a fire door is treated as a structural promise. Our door jambs and frames are made with precision-engineered profiles that ensure solid installation and long-term stability, whether the project involves mild steel (MS) or stainless steel (SS) construction.

For concrete wall installations, our engineers recommend using chemical anchors or expansion bolts, which deliver firm structural connection and preserve the door’s fire integrity throughout its service life. When installed on sandwich panel walls, Yuankai fire doors are secured using self-tapping screws or steel plate reinforcement, maintaining the panel’s insulation performance while ensuring the frame remains rigid and properly sealed.

All necessary fasteners, fixing accessories, and anchor materials are provided with the product, eliminating any on-site compatibility issues. For projects where the walls already contain embedded plates or anchor inserts, our design team adjusts the fixing drawings to achieve perfect alignment during installation.

This careful approach reflects Yuankai’s engineering philosophy: each door should not only pass fire testing but also stand firm under real-world installation conditions. That’s why our fire door systems are now trusted in factories, hospitals, food plants, and commercial facilities across Asia, the Middle East, and Europe.

6.Air Permeability Requirement — Ensuring Hygienic and Airtight Performance

In modern food processing plants, pharmaceutical factories, and cleanroom environments, even the smallest air leakage can compromise hygiene and safety. Henan Yuankai Door Industry Co., Ltd. designs every fire door with precise air-tight sealing systems to meet these demanding standards.

Our door structures are equipped with continuous compression seals around the entire perimeter—top, sides, and bottom—ensuring that no unfiltered air, dust, or smoke can pass through when the door is closed. The air permeability of Yuankai fire doors has been tested according to EN 1026 and ASTM E283 standards, achieving results that meet or exceed the requirements for clean industrial environments.

To ensure long-lasting performance, we use antibacterial and flame-retardant sealing materials that are resistant to chemical cleaning agents, UV exposure, and temperature fluctuations. The result is a reliable fire door solution that not only withstands fire but also maintains positive or negative pressure balance in controlled areas, ensuring safety and stability over time.

This strict attention to air sealing performance has made Yuankai’s doors a preferred choice for projects in food manufacturing plants, pharmaceutical laboratories, and cold storage facilities where clean air control is essential for both safety and compliance.

7.Door Seals (Single, Double & Sliding Doors) — Precision Sealing for Fire and Air Protection

A fire door is only as reliable as its seal. At Henan Yuankai Door Industry Co., Ltd., we design and manufacture door sealing systems that perform far beyond ordinary standards, ensuring protection not just from fire, but also from smoke, air leakage, and contamination.

Every Yuankai fire door—whether single-leaf, double-leaf, or sliding type—is fitted with continuous perimeter seals that compress evenly when the door closes. This design eliminates gaps at the top, sides, and threshold, achieving an airtight and smoke-tight seal. All seals are modular and replaceable, allowing easy maintenance and long service life without requiring special tools.

The sealing materials we use include EPDM, silicone, and thermoplastic elastomers, all tested for resistance to moisture, heat, UV, and chemical cleaning agents. For environments with stricter hygiene demands, such as food plants and hospitals, we offer antibacterial-grade seals that meet UL 94 and BS 476 flame-retardant standards.

When closed, the rubber or silicone seals are firmly pressed against both the frame and the floor, forming a complete barrier that maintains air pressure stability in controlled zones. This careful design is an essential part of Yuankai’s fire door solution, enhancing energy efficiency while contributing to safer and cleaner environments where air quality and fire protection are equally critical.

7-1.Performance & Standards — Certified Air and Fire Protection You Can Trust

At Henan Yuankai Door Industry Co., Ltd., performance is never just a claim—it’s something proven through testing and certification. All Yuankai fire doors and sealing systems are tested in accordance with international standards, including EN 1634-1, EN 1026, ASTM E283, UL 10C, and BS 476 Part 22. These certifications ensure that our doors not only resist fire and smoke but also maintain superior air permeability control for hygienic and controlled environments.

The air leakage rate of Yuankai fire doors meets the highest classification for industrial airtight systems, making them suitable for cleanrooms, laboratories, food factories, and pharmaceutical facilities. Independent laboratory tests confirm that our door seals can withstand positive and negative pressure differentials without deformation or performance loss.

Beyond air-tightness, all components—frames, seals, and cores—are manufactured using non-toxic, flame-retardant materials that comply with UL 94 and ISO 9001:2015 quality management standards. Our products are also engineered to maintain full functionality even after extended exposure to heat, moisture, or temperature fluctuations.

By maintaining consistent quality across every batch, Yuankai has built a reputation as a trusted global fire door supplier, delivering safe, reliable, and fully certified door systems to clients across Asia, the Middle East, Europe, and Africa.

7-2.Seal Construction & Material — Engineered for Durability and Hygienic Safety

The strength of a fire door lies not only in its core structure but also in the quality of its sealing system. Henan Yuankai Door Industry Co., Ltd. invests heavily in material engineering to ensure every seal performs consistently under demanding industrial conditions, forming a key part of our reliable fire door solution trusted by global clients.

Our door seals are manufactured using EPDM, silicone rubber, neoprene, and advanced thermoplastic elastomers (TPE)—materials chosen for their elastic recovery, flame resistance, and chemical stability. Each seal undergoes repeated compression and temperature-cycle testing to ensure it maintains its shape and airtight function even after years of operation.

For environments such as food manufacturing facilities, hospitals, and clean laboratories, Henan Yuankai Door Industry Co., Ltd. offers antibacterial-grade silicone seals that resist mold growth and meet FDA and ISO 22196 hygiene requirements. The materials are also UL 94 flame-retardant and tested under BS 476 Part 7 for surface spread of flame, ensuring both fire and smoke protection as part of a complete fire door solution designed for hygiene-sensitive applications.

Our seals are resistant to detergents, solvents, and UV exposure, making them ideal for locations requiring frequent cleaning or chemical disinfection. Each profile is precisely extruded for consistent compression performance, creating a perfect balance between airtightness and operational ease.

This meticulous approach to material selection ensures that Yuankai’s fire doors remain durable, safe, and reliable in every environment—from commercial kitchens to pharmaceutical clean zones.

7-3.Design & Installation — Practical Design, Simple Installation, and Long-Term Reliability

At Henan Yuankai Door Industry Co., Ltd., every door is designed not only to meet fire safety standards but also to make installation simple, accurate, and long-lasting. Our engineering team understands that real-world construction sites require practicality—so we ensure that each fire door system is both technically precise and installer-friendly.

Yuankai fire doors are supplied with complete fixing accessories, including anchors, screws, and fasteners, all matched to the project’s wall type—whether concrete, brick, or sandwich panel. The seal profiles are designed for easy alignment and optimal compression, typically requiring only 3–5 mm of closure pressure to form an effective air and smoke barrier.

The seals can be installed using clip-on, adhesive, or mechanical fastening methods, depending on site conditions. No special tools are needed for replacement, allowing maintenance teams to renew worn seals quickly without dismantling the entire frame. For large sliding or industrial doors, Yuankai provides customized adjustment kits that maintain perfect frame alignment even under pressure differentials or frequent operation.

This thoughtful design ensures that every Yuankai fire door can be installed efficiently—reducing labor time while preserving performance integrity. Whether for industrial warehouses, hospitals, or food plants, our doors are built for decades of reliable service with minimal maintenance.

Conclusion — Global Trust Built on Certified Fire Safety

For Henan Yuankai Door Industry Co., Ltd., every door represents more than a product—it’s a commitment to safety, precision, and trust. From airtight sealing to structural reinforcement, from flame resistance to hygiene control, each element is tested, certified, and designed to meet the world’s toughest standards.

With over a decade of export experience and certifications under UL, CE, and BS systems, Yuankai has become one of the most reliable China fire door manufacturers serving projects across Asia, the Middle East, Europe, and Africa. Our fire doors protect factories, hospitals, laboratories, and public buildings—places where safety cannot be compromised.

By combining scientific engineering, high-quality materials, and international compliance, Yuankai continues to deliver fire door solution that global partners can depend on. Our goal is simple yet essential: to help every client build safer, cleaner, and more efficient spaces—one certified door at a time.