A Practical Guide to Fire Door Hardware

When it comes to building safety, details matter more than most people realize. For contractors, real estate investors, purchasing managers, and door distributors, the choice of fire door hardware can determine whether a project passes inspection smoothly or runs into costly delays. This guide is designed with one clear purpose: to share practical knowledge that helps you make confident, informed decisions about the hardware that keeps fire doors reliable.

We know that sourcing fire-rated hinges, closers, locks, and seals often feels like navigating a maze of standards and certifications. It’s not just about finding products that look solid; it’s about ensuring that every hinge, latch, and seal is tested as part of a complete system. That’s why this article focuses less on sales talk and more on real guidance—what each piece of hardware does, why it matters, and how international standards like UL, CE, and NFPA shape the requirements. The aim is simple: to give you a clear, trustworthy roadmap for selecting the right fire door hardware, so that your projects are safer, smoother, and compliant from the very start.

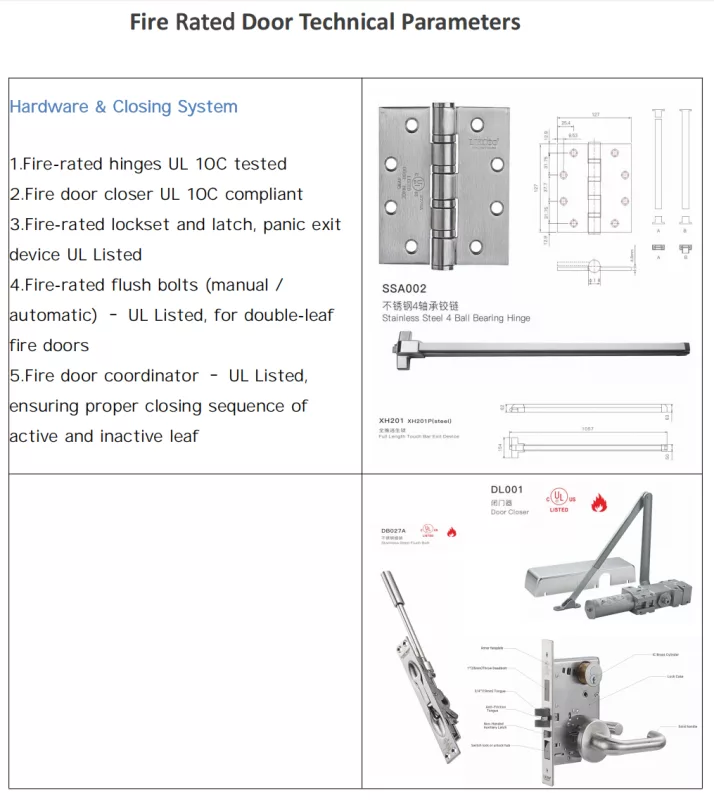

1.Fire Door Hinges Must Be Fire-Rated

When discussing fire rated door hardware, one of the most critical components is the hinge. A fire door cannot perform its role in an emergency if the hinges fail under extreme heat. Certified fire-rated hinges, tested under UL 10C or EN 1634 standards, ensure that the door remains securely in place even when exposed to fire for extended periods. Unlike ordinary hinges, these components are designed with thicker materials, heat-resistant alloys, and reinforced pins that prevent distortion or collapse during a fire.

In most professional applications, fire doors are installed with at least three fire-rated hinges. This configuration distributes the weight of the heavy steel or wooden fire door leaf, reducing stress on each hinge and maintaining structural stability. At YK Door Industry, we supply all fire rated door hardware, including hinges, closers, locks, and panic exit devices, ensuring compliance with international standards. Our recent investment in automated hinge production lines, CNC cutting machines, and robotic welding systems allows us to manufacture hardware with consistent precision and reliability.

Another important aspect is the integration of certified hinges into the complete door assembly. Hardware is not tested independently but as part of the entire fire door set. This guarantees that hinges work seamlessly with the frame, door leaf, seals, and closers. For contractors and distributors looking for a reliable supplier for all fire rated door hardware, YK Door Industry offers not only a wide range of certified hinges but also end-to-end solutions. We handle production, surface treatment, installation, and after-sales support, creating a one-stop service rarely found among competitors.

From recent large-scale projects in Southeast Asia and the Middle East, our experience shows that builders and fire safety inspectors pay special attention to hinge quality during inspections. Weak or uncertified hinges can result in failed fire safety audits, project delays, or even legal consequences. This is why sourcing from a professional fire door hardware supplier with proven track records is essential. YK Door Industry, with its expanded machinery fleet and strict in-house testing, ensures that every hinge leaving our factory meets the highest safety expectations.

By focusing on certified fire-rated hinges, contractors and developers can guarantee not only compliance but also the safety of building occupants. YK Door Industry’s complete in-house manufacturing chain—covering both fire doors and hardware accessories—demonstrates our commitment to providing the global market with durable, reliable, and fully certified fire protection solutions.

2.Control & Monitoring System

An advanced control and monitoring system is an indispensable part of modern fire rated door hardware. According to NFPA 80, fire doors must be integrated with the building’s fire alarm system to ensure immediate response in case of emergency. At YK Door Industry, our hardware solutions are designed to comply with UL 864 Fire Alarm Control requirements, offering contractors and project managers peace of mind that all installed components meet international safety standards.

The integration of smoke and heat detectors with fire doors enables automatic closing during fire events. This function prevents flames and toxic gases from spreading into protected compartments. A critical element of this system is the fail-safe closing mechanism, which guarantees that the door will close securely even during a power outage. By coordinating the fire door closer, certified UL listed hardware, and specialized fire door seals, the system provides a complete safety barrier against both fire and smoke.

In addition to safety, performance consistency matters. YK Door Industry has recently expanded its production capacity by adding automated assembly lines for electronic door monitoring devices and precision seal manufacturing. This investment allows us to deliver reliable, high-quality control systems paired with UL certified seals, ensuring a perfect match between mechanical hardware and electronic monitoring.

Our expertise extends to providing contractors and distributors with a supplier for all fire rated door hardware requirements. From hinges and closers to advanced fire alarm integration and smoke seals, we offer a comprehensive solution that reduces the need for multiple vendors. With recent projects across Europe and the Middle East, our integrated systems have consistently passed rigorous safety inspections, reinforcing our reputation as a trusted global manufacturer.

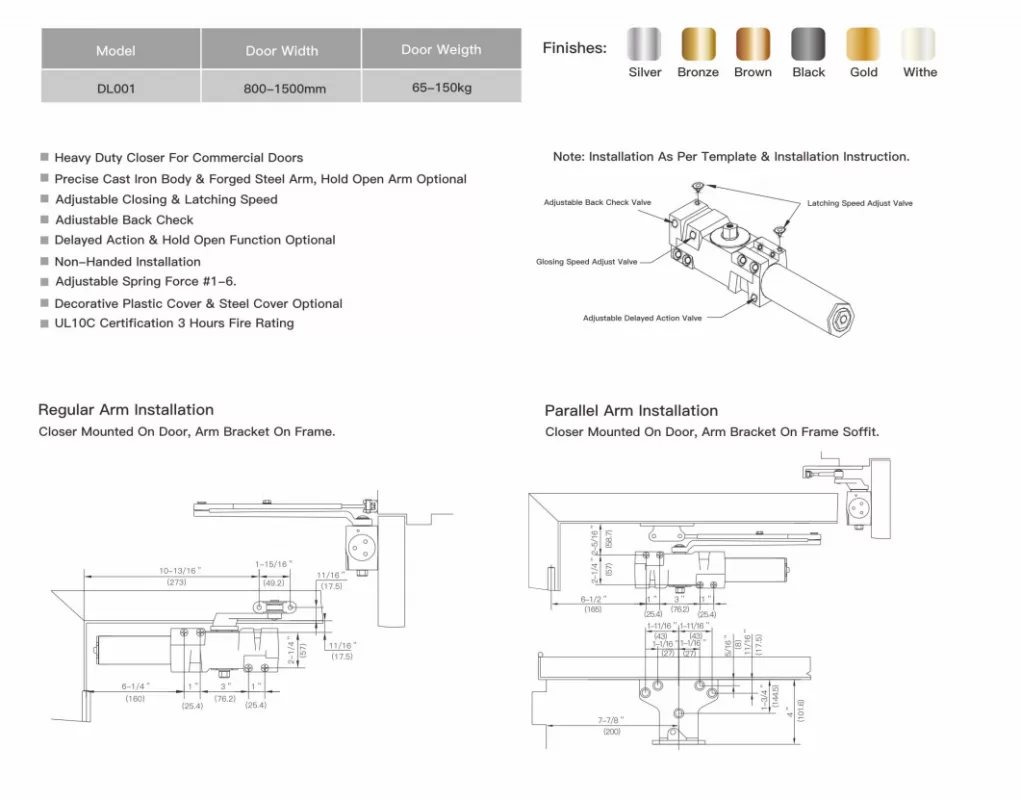

Door Closer DL001 Specifications

| Category | Details |

|---|---|

| Model | DL001 |

| Door Width | 800–1500 mm |

| Door Weight | 65–150 kg |

| Certification | UL10C, 3 Hours Fire Rating |

| Installation | Non-Handed, Regular Arm or Parallel Arm |

| Material | Cast Iron Body, Forged Steel Arm |

| Adjustable Features | Closing Speed, Latching Speed, Back Check, Delayed Action, Spring Force (#1–6) |

| Functions | Delayed Action & Hold Open (Optional), Non-Handed Installation |

| Covers | Decorative Plastic Cover or Steel Cover (Optional) |

| Finishes Available | Silver, Bronze, Brown, Black, Gold, White |

Installation Options

- Regular Arm Installation: Closer mounted on door, arm bracket on frame.

- Parallel Arm Installation: Closer mounted on door, arm bracket on frame soffit.

Key Adjustment Valves

- Adjustable Back Check Valve

- Closing Speed Adjust Valve

- Latching Speed Adjust Valve

- Adjustable Delayed Action Valve

For builders, architects, and safety engineers, working with YK Door Industry means gaining access to a one-stop partner that controls every stage of the process. By combining UL compliant monitoring systems with fire door seals and other certified accessories, we create a fully unified fire protection package designed to save lives and protect property.

3.Locks and Latches Need Fire Certification

Among all fire rated door hardware, locks and latches are often underestimated but play a decisive role in both security and fire protection. Fire-rated locks and latches are not only responsible for securing access against intrusion but must also maintain the integrity of the latch bolt when exposed to high temperatures. If uncertified components are used, the latch may deform, preventing the door from closing tightly during a fire. This could compromise the compartmentalization of smoke and flames, leading to severe safety hazards.

Certified fire-rated locks and latches are tested under internationally recognized standards. UL Listed locks undergo testing in accordance with UL 10C and related requirements in the United States. These tests focus on high-temperature endurance and functional reliability under direct fire exposure. CE Marked locks, on the other hand, are evaluated under EN 12209 and EN 1634-1 standards within the European Union, emphasizing not only fire resistance but also mechanical performance and durability. While both certifications guarantee safety, UL is more commonly demanded in the United States and Middle Eastern projects, whereas CE certification is essential for compliance within the European Economic Area.

Outside lever retracts latchbolt unless it is locked (made inoperative) by the toggle button.

Latchbolt can be retracted by key from the outside and by inside lever when the outside lever is locked.

Outside lever is locked and unlocked by the toggle button.

Key from the outside locks the outside lever only.

When latchbolt is retracted by the inside lever, the outside lever remains locked.

Auxiliary latch deadlocks the latchbolt when the door is closed.

Inside lever is always free for immediate egress.

At YK Door Industry, we supply all fire rated door hardware, ensuring our locks and latches are available in both UL Listed and CE Marked versions. This allows contractors and global distributors to meet the specific legal requirements of their regional markets. Our recent expansion includes precision machining centers and automated lock assembly lines, enabling us to deliver consistent quality across large production batches.

We also integrate these certified locks with other critical components, such as fire door closers, coordinators, and intumescent seals, to create a unified system tested as a complete assembly. For clients searching for a reliable supplier for all fire rated door hardware, YK Door Industry provides an end-to-end solution—from design and manufacturing to installation and compliance documentation. By offering both UL and CE certified locks and latches, we ensure that every project can achieve regulatory approval while maintaining the highest level of fire safety performance.

4.The Role of Panic Exit Devices

Panic exit devices, often referred to as push bars or crash bars, are essential components of fire rated door hardware. Their primary purpose is to allow rapid egress in emergency situations, ensuring that occupants can evacuate a building quickly and safely. By applying pressure to a horizontal bar, the door unlatches immediately without the need for keys or complex mechanisms, which is crucial when people are under stress or in low-visibility conditions caused by smoke.

In addition to providing fast exit routes, panic exit devices are designed to maintain the fire-resistance rating of the door assembly. This means that even while enabling quick evacuation, they do not compromise the integrity of the fire barrier. Properly tested devices comply with international standards such as EN 1125 in Europe and UL 305 in the United States, both of which set performance requirements for durability, reliability, and safety.

The technical design of panic exit devices often includes reinforced latch mechanisms and fire-rated materials capable of withstanding high temperatures. They are also engineered to accommodate heavy pedestrian flow, making them suitable for high-occupancy environments such as schools, hospitals, airports, and shopping centers. Regular inspection and maintenance are critical, as worn or damaged devices may hinder evacuation and result in safety violations.

Ultimately, the role of panic exit devices extends beyond convenience. They are life-saving tools that combine mechanical simplicity with fire safety compliance. By ensuring that every fire door equipped with panic exit hardware meets recognized standards, building owners and safety engineers can provide both accessibility and protection in times of crisis.

5.Flush Bolts and Coordinators for Double Doors

When it comes to double-leaf fire doors, the performance of the assembly relies on more than hinges and closers. Two elements—flush bolts and door coordinators—play a decisive role in ensuring that both active and inactive leaves operate correctly under normal use and in fire conditions.

The Function of Flush Bolts

Flush bolts secure the inactive leaf of a double door by locking it into the frame or floor. In fire-rated assemblies, these bolts must be constructed from materials tested to withstand high temperatures and maintain their locking function when flames or heat pressure intensify. A poorly designed flush bolt can distort under fire exposure, leaving the leaf unsecured and compromising the entire fire barrier. Certified fire-rated flush bolts undergo endurance tests to ensure that, even after extended fire exposure, they remain functional enough to keep the door sealed.

The Role of Coordinators

Coordinators ensure the correct closing sequence of double doors. In an emergency, the inactive leaf must close first so that the active leaf can latch properly. Without a coordinator, the leaves may close out of order, leaving gaps that allow smoke and fire to spread. Coordinators are mechanical devices, often mounted at the top of the frame, and are required by standards such as NFPA 80 for many double-door assemblies. Their design must accommodate the weight of heavy fire-rated doors, resist wear from frequent use, and guarantee reliable performance during a crisis.

Interdependence of Components

The relationship between flush bolts and coordinators illustrates the interdependence of fire door hardware. One ensures security, the other guarantees correct operation, and together they allow the door to meet the intended fire-resistance rating. In modern specifications, it is common to require both UL-listed flush bolts and coordinators in double-door fire-rated assemblies to comply with safety codes in the United States, while CE-marked components serve the same function under European regulations.

Practical Implications

In practice, designers and facility managers must account for these components early in a project’s planning stage. Omitting or under-specifying them can result in failed inspections, expensive retrofits, or worse—reduced protection during a real fire. Coordinated selection of these accessories ensures that the door assembly functions as a unified system rather than a set of independent parts.

By treating flush bolts and coordinators as critical safety hardware, not optional accessories, professionals in construction and facility management strengthen the reliability of fire-rated doors. Their contribution goes beyond mechanical support; they are integral to preserving life safety and structural compliance in complex building environments.

6.Vision Panels Must Use Fire-Rated Glass

Vision panels are often requested in fire-rated doors to balance safety with visibility. They provide occupants and security staff with clear sightlines while still maintaining the fire-resistance of the door assembly. However, not all glass is equal when it comes to fire protection. Only fire-rated glass, tested and certified under standards such as UL 10C, EN 1634-1, or BS 476 Part 22, can be used in these applications. Ordinary glazing fails rapidly when exposed to fire, while certified fire-rated glazing is designed to resist heat, flames, and thermal shock for specified durations.

Types of Fire-Rated Glass

There are several categories of fire-rated glazing used in vision panels. Wired glass is the traditional option, incorporating a mesh that holds the glass together under heat stress, preventing shattering. More modern alternatives include ceramic glass, known for its high thermal stability, and insulated fire-resistant glass units, which combine multiple layers with intumescent interlayers that expand under heat to block radiant energy. Each option has its own strengths: wired glass is cost-effective, ceramic offers clarity and durability, and insulated units provide enhanced performance in longer fire ratings.

Frame and Beading Requirements

A vision panel is not just about the glass itself but also about how it is mounted. Fire-rated glass must be set into frames and beadings made from materials that can withstand heat without failure. Steel, stainless steel, or specialized fire-resistant timber frames are common choices. The beading is often fitted with intumescent seals that expand under fire exposure, closing any gaps between the glazing and the frame. This integration ensures that the vision panel contributes to the door’s certified fire resistance rather than becoming a point of weakness.

Regulatory Considerations

International codes are explicit about vision panel requirements. For example, NFPA 80 in the United States stipulates maximum allowable sizes for glazing in fire-rated doors, while European and British standards impose similar limitations. These restrictions exist because larger glass areas are more vulnerable to heat stress, and maintaining structural integrity is critical. Compliance with size limits, combined with the use of UL or CE certified glazing, ensures that the panel passes fire tests and satisfies building inspectors during safety audits.

Practical Applications

Vision panels serve both safety and functionality. In hospitals, they allow staff to monitor patients in corridors without opening doors. In schools, they help teachers keep sight of hallways while maintaining compartmentalization. In industrial settings, they allow for safe monitoring of machinery areas without breaching fire zones. These examples demonstrate that vision panels are not decorative but serve a strategic purpose in building safety and operation.

Maintenance and Inspection

Like other fire-rated hardware, vision panels require periodic inspection. Building managers must ensure that the glass has not been replaced with non-rated glazing during repairs, that seals remain intact, and that beadings are secure. Any compromise in these components reduces the fire-resistance of the door assembly. Regular checks, as required by NFPA 80 and similar standards, ensure that vision panels remain reliable under real emergency conditions.

By specifying certified fire-rated glass and ensuring proper installation, designers and building owners can enhance visibility without sacrificing safety. Vision panels, when properly integrated, combine transparency and protection, making them essential features in many fire-rated door designs.

7.Intumescent and Smoke Seals Are Essential

Fire-rated doors are very different from ordinary residential or interior doors, and one of the clearest distinctions lies in the use of intumescent and smoke seals. While a standard wooden or metal household door may provide privacy and some sound insulation, it is not designed to withstand fire or restrict smoke spread. In contrast, fire-rated doors are fitted with specialized seals that expand and form tight barriers when exposed to heat, ensuring that fire compartments remain secure during emergencies.

How Intumescent Seals Work

Intumescent seals are made from materials that expand many times their original volume when subjected to high temperatures. This swelling fills gaps between the door leaf and the frame, preventing flames and hot gases from penetrating. Ordinary domestic doors lack this critical feature, leaving large clearances around the edges through which smoke and fire can easily pass. In fire-rated assemblies, the seal’s rapid expansion is a decisive factor in achieving certified fire resistance ratings.

Smoke Seal Functionality

In addition to intumescent materials, many fire-rated doors incorporate smoke seals. These are designed to restrict cold smoke movement at the early stages of a fire, before temperatures rise enough to activate intumescent expansion. Domestic and non-rated doors typically have only decorative or acoustic strips that cannot provide meaningful smoke control. By combining intumescent and smoke seals, fire-rated doors protect occupants from one of the leading causes of fire-related deaths—smoke inhalation.

International Standards Comparison

Different countries codify the necessity of seals in their fire safety standards. In the United States, NFPA 80 requires fire doors to be equipped with gasketing or intumescent seals as part of their assembly. The UL 10C test method also evaluates the performance of these seals under fire conditions. In Europe, EN 1634-1 mandates the use of intumescent seals in achieving required fire resistance classifications, and EN 13501-2 outlines the criteria for smoke control. The United Kingdom’s BS 476 Part 22 and associated documents emphasize intumescent strips as mandatory for certified fire doors. In China, GB 12955 requires both fire and smoke seals in all standardized fire door products. By comparison, non-rated domestic doors across these regions are not subjected to such rigorous demands and are therefore unsuitable as barriers in fire zones.

Practical Implications for Building Safety

The difference between a fire-rated door with seals and a standard interior door is not minor—it can be the difference between life and death in an actual fire. Certified seals extend the time available for evacuation, reduce property damage, and allow fire services to respond more effectively. Without them, even the heaviest steel door cannot prevent smoke infiltration or heat transfer at vulnerable gaps.

Conclusion

Intumescent and smoke seals are not optional add-ons; they are essential components that distinguish fire-rated doors from ordinary household or office doors. Their presence is reinforced by international standards in every major market, from UL in the United States to CE in Europe, BS in the UK, and CCC in China. Comparing the two categories of doors highlights the importance of seals in ensuring life safety. For architects, builders, and safety officers, specifying fire-rated seals is an integral part of compliance and a fundamental commitment to occupant protection.

8.Hardware Must Be Tested with the Door Assembly

One of the most important principles in fire door engineering is that hardware cannot be evaluated in isolation. Hinges, locks, closers, seals, and vision panels may each carry certifications, but in real-world fire scenarios they function as a system rather than as independent parts. For this reason, international standards such as UL 10C, EN 1634-1, and BS 476 Part 22 require complete door assemblies—including the leaf, frame, and all hardware—to undergo full-scale fire resistance testing. During these tests, the interaction between each component is measured: for example, whether the hinges can still hold the door leaf while the closer forces it to shut, or whether the latch bolt remains aligned with the strike plate under high thermal pressure. Testing the entire assembly ensures that the weakest link is identified and eliminated, providing assurance that the door as a unit will contain fire and smoke for the rated duration.

This system-based approach highlights why substituting uncertified or incompatible hardware is risky. Even if a hinge or lock carries an individual UL or CE certificate, replacing the tested component with a similar-looking alternative can invalidate the fire rating of the entire door set. In practice, building inspectors and fire marshals look for evidence that all hardware installed on site matches the components listed in the door’s official certification documents. For architects, contractors, and safety engineers, this means that procurement must be precise and installation must follow the approved assembly details exactly. Ignoring this requirement may lead not only to failed inspections and costly retrofits but also to compromised safety during an actual emergency. Therefore, hardware testing within the complete door assembly is not just a technicality—it is a safeguard that upholds the fundamental purpose of fire doors: to preserve life and property in the face of fire.

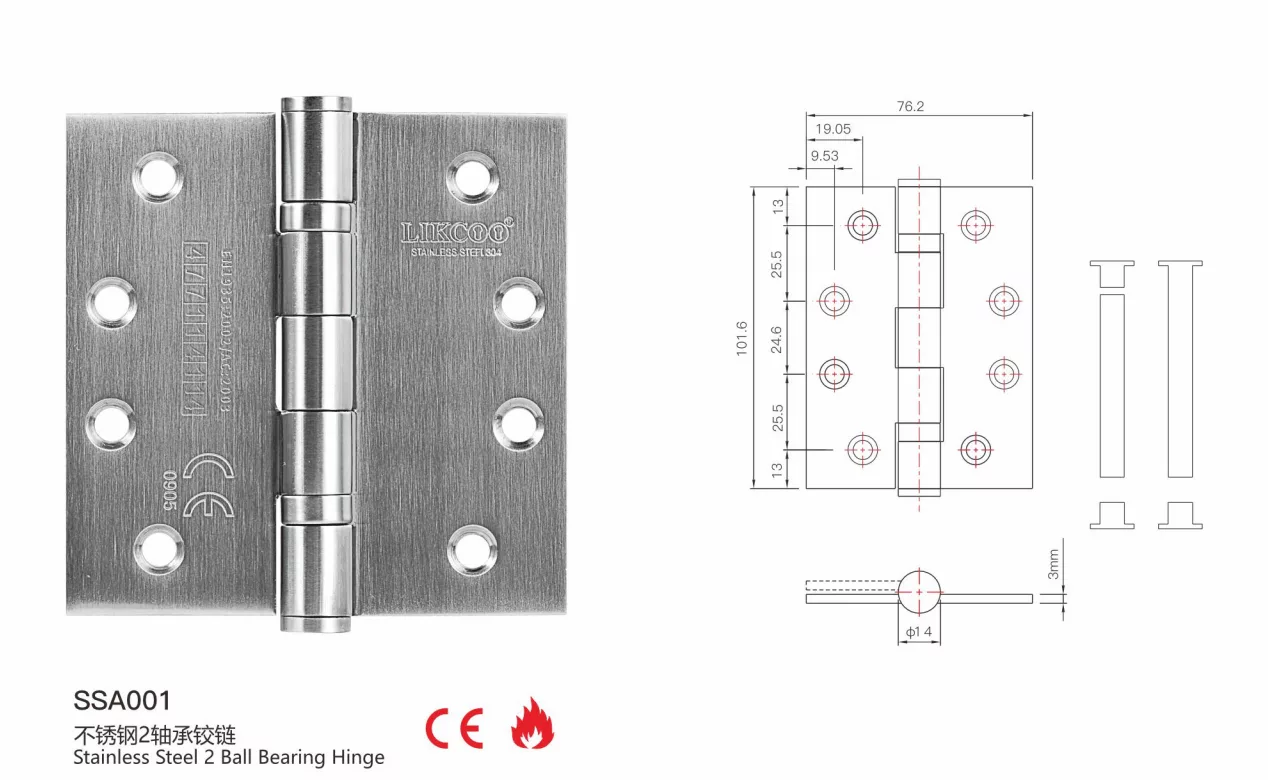

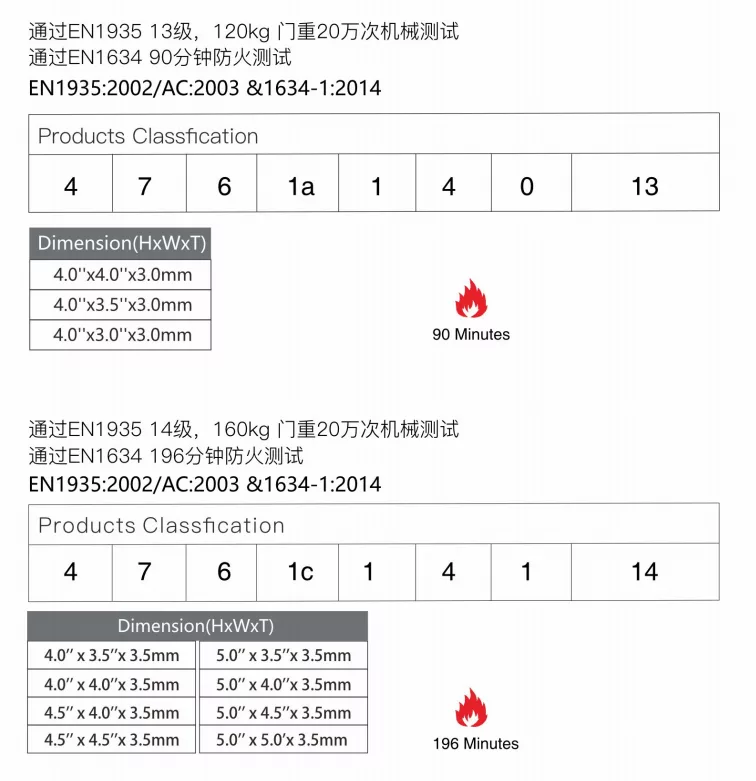

Test Report Summary

90 Minutes Fire Test (EN1634)

- Mechanical Test: EN1935 Grade 13, 120kg, 200,000 cycles

- Standards: EN1935:2002/AC:2003 & EN1634-1:2014

| Products Classification | 4 | 7 | 6 | 1a | 1 | 4 | 0 | 13 |

|---|

| Dimension (H×W×T) |

| 4.0″ × 4.0″ × 3.0mm |

| 4.0″ × 3.5″ × 3.0mm |

| 4.0″ × 3.0″ × 3.0mm |

196 Minutes Fire Test (EN1634)

- Mechanical Test: EN1935 Grade 14, 160kg, 200,000 cycles

- Standards: EN1935:2002/AC:2003 & EN1634-1:2014

| Products Classification | 4 | 7 | 6 | 1c | 1 | 4 | 1 | 14 |

| Dimension (H×W×T) |

| 4.0″ × 3.5″ × 3.5mm |

| 4.0″ × 4.0″ × 3.5mm |

| 4.5″ × 4.0″ × 3.5mm |

| 4.5″ × 4.5″ × 3.5mm |

| 5.0″ × 3.5″ × 3.5mm |

| 5.0″ × 4.0″ × 3.5mm |

| 5.0″ × 4.5″ × 3.5mm |

| 5.0″ × 5.0″ × 3.5mm |

9.Regular Maintenance Is Required by NFPA 80

The effectiveness of fire doors is not determined solely at the point of manufacture or installation; it must be preserved through regular inspection and maintenance. According to NFPA 80, which governs fire door assemblies in the United States, annual inspections are mandatory to verify that doors and their hardware remain fully functional. This includes ensuring that hinges are tight, closers shut the door completely, locks and latches engage properly, seals are intact, and vision panels have not been replaced with non-rated glass. Even small issues, such as worn gasketing or loose screws, can have significant consequences during a fire, as they compromise the ability of the assembly to contain flames and smoke. NFPA 80 emphasizes that inspections should be performed by qualified personnel familiar with both the code requirements and the technical aspects of fire door assemblies.

The importance of this maintenance requirement is reinforced by case studies and real-world incidents. In multiple fire investigations, doors that failed to perform were often found to have been altered, neglected, or fitted with incompatible hardware. By contrast, buildings with documented NFPA 80 inspection programs demonstrated higher levels of safety compliance and reduced liability for owners and managers. The standard’s intent is not simply to create a regulatory hurdle but to establish a culture of accountability: fire doors are life-safety systems, and like sprinklers or alarms, they must be checked and serviced regularly. Beyond the U.S., similar maintenance obligations exist under EN 16034 in Europe and BS 9999 in the UK, reflecting the global recognition that periodic inspection is as essential as initial certification. By aligning operations with NFPA 80, facility managers not only meet code but also ensure that fire-rated doors fulfill their primary role—protecting occupants and property when every second counts.

10.Choosing Certified Manufacturers Matters

After exploring the ten essential aspects of fire door hardware—from hinges, closers, locks, and panic devices to flush bolts, coordinators, vision panels, seals, and the importance of full assembly testing and regular maintenance—it becomes clear that certified manufacturers are the backbone of reliable fire safety solutions. Each element on its own is vital, but only a professional supplier with integrated capabilities can bring all these components together into a compliant, efficient, and trustworthy system.

A certified manufacturer must demonstrate not only adherence to global standards such as UL 10C, NFPA 80, EN 1634, and BS 476, but also the ability to provide documentation, testing reports, and ongoing quality assurance. This ensures that every hinge, latch, seal, or vision panel installed on site is traceable to a certified production batch. For suppliers, it is not enough to sell hardware individually; they must act as long-term partners to contractors, architects, and safety engineers, guaranteeing that each project remains compliant from specification through installation and beyond.

YK Door Industry, based in Guangdong, China, exemplifies the advantages of working with a vertically integrated supplier for all fire rated door hardware. Our dedicated hardware factory is equipped with advanced CNC machining centers, automated hinge production lines, robotic welding equipment, and precision assembly units for locks and panic devices. This comprehensive production line allows us to manage every stage of the process, from raw material selection and fabrication to finishing and installation support. By consolidating production under one roof, we deliver consistency, reduce lead times, and ensure that all parts are compatible as part of a tested fire door assembly.

Being both a door manufacturer and a hardware supplier, YK Door Industry offers unique advantages that distributors and contractors value. Instead of sourcing hinges from one company, closers from another, and seals from a third, clients receive an integrated package tested and proven to perform as a complete system. Our role extends beyond manufacturing; we provide technical consultation, compliance guidance, and after-sales service, ensuring that projects pass inspections without delays. For international partners, we also offer dual certification options—UL for projects in the U.S. and Middle East, CE for Europe—so that hardware meets the precise regulatory environment of each market.

Ultimately, choosing certified manufacturers is about more than compliance. It is about accountability, reliability, and trust. YK Door Industry, with its hardware factory in Guangdong and its continuous investment in cutting-edge machinery, embodies these values. By bringing together all ten critical aspects of fire door hardware under one integrated supply chain, we provide global clients with a level of assurance that only a fully certified, technologically advanced supplier can offer. In a field where performance translates directly into life safety, working with a proven manufacturer is not just a recommendation—it is a necessity.

Pingback: China Windows and Doors Market Overview (Part 2) - YK | Fire Doors | Fire Windows | Fire Shutters