Choosing the Right Fire Rated Door for a 2 Hour Fire Rated Wall – A Complete Guide by YK Commercial Door Company

In the realm of building fire safety, there is absolutely no room for compromise. Whether you’re protecting a commercial facility, healthcare environment, school, or high-rise office building, installing the proper fire-rated doors and components is critical. YK Commercial Door Company, a trusted manufacturer of certified fire-rated wood doors and metal frames, explains everything you need to know when selecting the right fire-rated solution for a 2-hour fire-rated wall.

Why a 90 Minute Fire Rated Door Is Required for a 2 Hour Wall

According to fire protection standards, a 2 hour fire rated wall door requirement calls for a 90-minute fire-rated door. This gives building occupants enough time to evacuate safely and allows firefighters a window to contain the fire. At YK Commercial Door Company, we specialize in supplying 90-minute fire-rated wood and metal doors that meet or exceed UL and Intertek standards, ensuring both safety and code compliance.

Complete Fire Door Packages with Fast Lead Time

We understand that construction deadlines are tight. That’s why YK Commercial Door Company offers complete door, frame, and hardware packages with rapid production. Standard fire-rated stock items ship in just 3-5 business days. With our instant pricing system, you can build a quote in minutes and customize your door’s size, finish, and hardware configuration online.

Industry Standard Sizes & Custom Dimensions

All our fire-rated commercial doors are manufactured with 1-3/4” thickness and are available in standard widths up to 4’0” and heights up to 8’0”. We also accommodate custom-sized fire doors with trimming, restyling, or undersized widths for continuous hinge applications. Whether you’re outfitting a 3068 opening or need a custom 3880, YK provides flexibility to fit your project.

Common Standard Sizes

| Call Size | Width | Height |

|---|---|---|

| 3068 | 36″ | 80″ |

| 3070 | 36″ | 84″ |

| 4080 | 48″ | 96″ |

(Actual door dimensions are slightly undersized for proper fitting and clearance.)

Fire Rating for Doors: Understanding Standards, Testing, and Building Integration

At YK fire rated doors supplier, we recognize that door fire ratings are not just technical specifications—they are essential safeguards in every building’s fire protection strategy. Whether you’re securing industrial spaces with metal commercial doors or protecting emergency routes with fire exit doors, understanding how fire ratings work is critical to code compliance and occupant safety.

Why Fire Ratings Matter in Door Systems

Fire-rated doors form a critical barrier against the rapid spread of fire, smoke, and radiant heat. Their primary function is to compartmentalize fire incidents, allowing for safe evacuation and reducing structural damage. Properly installed and rated commercial steel doors and frames can provide valuable time for emergency responders and ensure continuity of escape routes.

Fire Door Ratings and What They Mean

The fire door rating indicates how long a door assembly can withstand fire exposure without failing. Expressed in time intervals—commonly 20, 45, 60, 90, or 180 minutes—these ratings guide architects, engineers, and certified fire door inspectors in selecting the correct doors for various applications.

- 20-minute fire doors are often used in corridors or rooms with low fire risk. These doors focus on smoke and flame containment and are usually exempt from hose stream testing.

- 45-minute fire doors suit storage areas, stairwells, or exterior walls with moderate fire exposure. They must pass both endurance and hose stream tests.

- 60-minute fire doors are suitable for partitioning spaces with higher containment needs.

- 90-minute fire doors are used in high-risk zones such as stair enclosures and vertical shafts—critical evacuation routes requiring robust protection.

- 180-minute fire doors, or fire rated steel doors, are installed in hazardous or high-value areas like industrial control rooms and chemical storage facilities.

When choosing a fire-rated door, one must consider the door fire rating in a 2 hour wall to ensure compliance with fire barrier continuity.

Fire Door Testing Standards

All emergency fire exit doors and fire-rated assemblies are subject to rigorous testing by accredited laboratories. The results confirm compliance with national safety codes and ensure the door’s functionality in a fire event.

Key standards include:

- UL 10B: Tests the door’s integrity under neutral or negative pressure without simulating real fire dynamics.

- UL 10C: Introduced to replicate real fire conditions, this standard measures the door’s performance under positive pressure, where hot gases push against the assembly.

- NFPA 252: Offers comprehensive fire testing, including hose stream and positive pressure scenarios, as required by modern codes.

Neutral vs. Positive Pressure: Why It Matters

Earlier test methods evaluated fire doors under neutral or negative pressure conditions, which failed to replicate the intense dynamics of real fires. However, since the late 1990s, industry standards for fire rating for doors have evolved to require positive pressure testing for more accurate performance assessment.

In an actual fire, high-pressure zones form above the door while low-pressure zones develop near the floor. Positive pressure tests—mandated by UL 10C and NFPA 252—simulate these real-world conditions to ensure that fire exit doors can resist the intrusion of flames and smoke under pressure.

This advancement significantly enhances the reliability of commercial fire-rated doors, especially fire rated steel doors, confirming they are equipped to perform in the most demanding emergency scenarios. It’s a vital consideration for any facility that prioritizes safety, code compliance, and life-saving performance.

What Is a Fire-Rated Door Assembly?

A fire-rated door is more than just a single panel—it’s a fully integrated assembly designed to meet the required fire rating for doors in commercial and industrial environments. A complete assembly typically includes:

- Door Leaf: Made from steel, wood, or advanced composite materials specifically engineered to resist fire.

- Frame: Fabricated from fire-rated steel or aluminum, the frame must match or exceed the door’s designated fire rating.

- Hardware: All components—hinges, locks, closers, and latches—must be certified to function under heat and comply with the required fire rating for doors.

- Glazing: When included, fire-rated glass must block flame and heat transmission while preserving visibility and structural integrity.

Each element plays a critical role in maintaining the door assembly’s fire integrity. This is especially vital in commercial steel doors and frames, which are commonly installed in egress routes, stairwells, and compartmentalized zones to delay fire spread and protect building occupants.

Common Materials and Their Use Cases

- Wood doors (treated with fire-retardant chemicals) are often found in offices and residential buildings.

- Steel doors, especially metal commercial doors, are widely used in industrial zones due to their durability and heat tolerance.

- Fiberglass doors are preferred in corrosive or humid environments.

- Fire-rated glazing enhances aesthetics and light transmission without compromising fire protection.

Door Specifications

- Thickness: 1-3/4″ standard

- Core Options: Mineral core and particle board

- Undercut: 3/4″ standard

- Fire Ratings Available: 20, 45, 60, and 90 minutes

- Finishes: Unfinished, Clear Pre-finished, Mahogany, Dark Walnut, Autumn Oak, and more

- Preps: 161 Cylindrical Lock, 86 Mortise, Panic Hardware, Deadbolt, Lite & Louver Cutouts

- Compatible Brands: Steelcraft, Mesker, Ceco, Republic, Curries, Pioneer, and more

Certified Fire Rated Hardware Is a Must

A fire-rated door can only perform as intended when equipped with certified fire-rated hardware that meets the required fire rating for doors. At YK Commercial Door Company, we offer a full range of compliant hardware solutions, including:

- Hinges and pivots with proper fire labels

- Fire-rated locks and deadbolts

- Closers and spring hinges that keep the door securely closed during fire conditions

- Intumescent gasketing that maintains integrity without compromising the door’s rating

All hardware provided by YK complies with ANSI A208.1 standards and the specific fire rating requirements applicable to various door assemblies. Our components are rigorously tested, including fire endurance and hose stream evaluations, to ensure that doors stay latched and sealed—even under extreme heat and high-pressure water spray.

Ensuring proper hardware is essential not just for code compliance, but for maintaining the complete fire rating for doors in any commercial or industrial application.

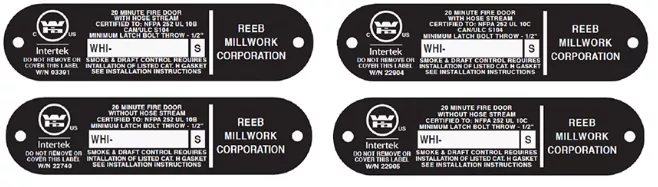

Fire Tests & Certifications

Fire-rated assemblies are tested at independent laboratories such as UL (Underwriters Laboratories) and Intertek (Warnock Hersey). These tests include:

- Fire Resistance Test – exposing the assembly to extreme heat in a furnace

- Hose Stream Test – spraying cold water after heating to simulate real emergency response conditions

Only hardware and assemblies listed in directories such as UL’s Fire Resistance Directory or Intertek’s Listed Product Directory can be used in certified fire door setups.

Specialty Fire Rated Products for High-Risk Applications

In addition to standard fire doors, YK Commercial Door Company offers fire-rated specialty products including:

- Acoustic Fire Rated Doors

- Blast and Pressure-Resistant Doors

- Bulletproof Fire Doors

- Windstorm-Resistant Fire Doors

These specialty doors combine life safety with added protection against environmental, security, or mechanical threats.

Optimized Draft: Technical Guide to Fire-Rated Doors – Temperature Rise, Smoke Control, Glazing, and Compliance Labels

1. Temperature Rise Test: Limiting Heat Transfer for Occupant Safety

The temperature rise test evaluates a fire-rated door’s ability to restrict heat transmission from the fire-exposed side to the non-fire side. This performance is critical in scenarios where evacuees may come into close contact with the door—such as stairwells or corridors—during emergency egress.

Testing Procedure:

- The door assembly undergoes a standard fire endurance test.

- Within the first 30 minutes, the temperature on the unexposed side is recorded to determine the rise above ambient temperature.

Evaluation Standards:

- 250°F temperature-rise doors offer the highest level of protection.

- Doors rated at 450°F or 650°F offer moderate thermal resistance.

- All temperature-rise rated doors must also pass the hose stream test, which verifies structural integrity post-fire exposure.

Key Significance:

Temperature-rise rated fire doors significantly reduce the risk of burns during evacuation, making them essential for fire-rated corridors and vertical shafts.

2. Smoke and Draft Control Testing (UL 1784)

Preventing the passage of smoke and toxic gases is equally important as resisting flames. The UL 1784 smoke and draft control test ensures that doors serve as effective barriers against harmful smoke infiltration.

Test Methodology:

- The door assembly is tested for air leakage under both ambient and elevated temperature conditions.

- Pressure differentials simulate fire conditions to assess leakage performance.

Compliance Criteria:

- Doors must stay within prescribed leakage thresholds.

- Successful assemblies bear an “S” label, denoting smoke-rated fire door compliance.

Importance:

Smoke-rated doors are vital for life safety in fire-rated corridors, preventing smoke spread that could obscure visibility, hinder evacuation, and cause smoke inhalation fatalities.

3. Fire-Resistive vs. Fire-Protective Doors

Understanding the distinction between fire-protective and fire-resistive doors is essential for selecting the right solution based on code requirements and application.

| Feature | Fire-Protective Doors | Fire-Resistive Doors |

|---|---|---|

| Function | Blocks flames and smoke | Blocks flames, smoke, and heat |

| Heat Transfer Resistance | No | Yes (includes temperature-rise performance) |

| Common Applications | Hallways, elevator lobbies | Stairwells, exit passageways |

| Glazing Limits | Smaller vision panels | Larger vision areas with resistive glazing |

Temperature-Rise Doors fall under the fire-resistive category, designed to restrict heat transmission and ensure safe passage even in proximity to intense fire exposure.

4. Glazing in Fire-Rated Doors: Safety Meets Visibility

Modern steel fire doors, particularly in commercial and industrial environments, often incorporate fire-rated glazing to enhance visibility and functionality while maintaining essential safety standards. The choice of glazing material depends significantly on the required fire rating for doors, which determines how long the door assembly can resist fire, smoke, and heat transmission.

Glazing Types:

- Fire-Protective Glazing

Designed to resist flames and smoke but allows the transmission of radiant heat.

Commonly used in doors with a fire rating of 20 to 45 minutes, typically featuring small vision panels.

Examples: Tempered glass, ceramic glass. - Fire-Resistive Glazing

Provides a higher level of protection by blocking flames, smoke, and both radiant and conductive heat.

Suitable for door assemblies with a fire rating for doors ranging from 60 to 120 minutes and larger glazed openings.

Examples: Multi-laminated glass, intumescent glazing.

Applications:

Fire-rated glazing is ideal for stairwells, rated partitions, and doors that require visibility without compromising containment. It enables first responders and occupants to assess interior conditions quickly and safely during a fire, thus improving evacuation routes and response time.

5. How to Identify and Verify Fire Door Ratings

Fire door labels are essential for confirming a door’s rating and verifying its compliance with building codes. These are typically affixed to the top, hinge edge, or bottom of the door and should remain visible at all times.

What to Look For:

- Testing Agency Mark (e.g., UL, WH)

- Fire Rating (e.g., 45 MIN, 90 MIN, 3 HR)

- Temperature Rise Rating (e.g., “T” label)

- Smoke Rating (e.g., “S” label, per UL 1784)

- Approved Applications (e.g., “D” for door assemblies)

Example Label:

“D-H-90” → Door application, passed hose stream test, 90-minute fire rating.

If the label is missing or painted over, the door is not compliant until verified by the Authority Having Jurisdiction (AHJ) or replaced.

6. Compliance When Modifying Fire Doors

Any modification to a fire-rated door or its components—such as glazing, hardware, or frame—must maintain compliance with the original testing and labeling. Altering a door without proper certification can void its fire rating.

Examples of Risky Modifications:

- Replacing a rated closer with a non-rated one.

- Installing non-compliant glazing.

- Drilling holes or resizing the vision panel beyond approved limits.

Always consult the door manufacturer or AHJ before proceeding with alterations.

7. Fire-Rated Glass Labeling

All certified fire-rated glazing used in doors must feature permanent, legible markings, often etched into the glass corner.

Typical Label Indicators:

- Fire rating duration (e.g., “45 MIN”)

- Application type: “D” (door), “W” (wall), “H” (hose stream tested)

- Compliance with temperature rise (if applicable)

Example:

“D-H-45” = For door assemblies, hose stream tested, 45-minute rating.

Proper labeling ensures building inspectors, facility managers, and safety personnel can verify that the door system meets code-mandated fire and life safety requirements.

The YK Advantage – Expertise and Responsiveness

At YK Commercial Door Company, we bring together years of technical fire safety expertise with fast turnaround times, competitive pricing, and flexible customization options. Whether you’re sourcing a single unit or outfitting an entire multi-story facility, we deliver high-performance, code-compliant solutions tailored to your needs.

Our team understands the critical role of selecting the right fire rating for doors, especially in commercial and industrial applications where compliance and safety cannot be compromised. From 20-minute to 3-hour rated doors, we help you navigate rating requirements and choose assemblies that meet local codes and functional demands.

For detailed sizing, custom orders, or certified hardware combinations, contact YK today. Or visit our website to build an instant quote, explore our fire-rated product options, and download complete specifications.

Common Misconceptions About Fire-Rated Doors: A Technical Clarification

Wired Glass vs. Modern Fire-Rated Glazing

One of the most enduring misconceptions about fire-rated doors is the continued reliance on wired glass. For decades, wired glass was widely used in fire door vision panels due to its perceived fire-resistant qualities. However, this belief no longer holds under modern safety standards.

Why Wired Glass Is No Longer Considered Safe:

- The embedded wire mesh compromises structural integrity, making the glass more prone to shattering on impact.

- Shattered wired glass poses serious injury risks, exposing sharp wires and jagged edges.

- Wired glass fails to meet modern impact safety standards, especially in areas like schools, hospitals, and sports facilities.

Modern Fire-Rated Glazing:

- Materials such as tempered laminated glass or ceramic fire-rated glass offer both fire resistance and impact safety.

- Certified by bodies like the Consumer Product Safety Commission (CPSC), these alternatives meet stringent codes for both thermal performance and occupant safety.

- Clearer aesthetics and superior optical performance make modern fire-rated glazing ideal for architectural applications without compromising on life safety.

Exemptions and Code Evolution: Staying Updated Is Critical

Another widespread misunderstanding is the belief that legacy exemptions still apply to fire-rated doors in older buildings. While these exemptions once permitted the use of wired glass and underspecified assemblies in certain applications, code revisions have largely eliminated such exceptions.

Key Regulatory Updates:

- 2003 IBC (International Building Code): Removed wired glass exemptions in educational and athletic facilities.

- 2012 IBC: Clarified that fire-protective glazing cannot exceed 100 square inches in doors rated over 45 minutes, encouraging use of fire-resistive glazing for larger openings.

- Current codes emphasize radiant heat resistance as part of total fire protection, particularly for vision panels in rated doors.

Takeaway:

Compliance is not static. Professionals must continually reference updated building codes and product certifications to ensure that all fire-rated door components meet current performance requirements.

Fire Door Frames and Compatibility: Why the Frame Matters as Much as the Door

The Role of Fire-Rated Frames in Assembly Performance

A fire-rated door is only as effective as the entire assembly, which includes the frame, hardware, seals, and glazing. The door frame, in particular, plays a pivotal role in maintaining the structural integrity of the opening during a fire.

Frame Failure = Assembly Failure

- An unrated or incompatible frame can allow fire, smoke, and heat to breach the protective barrier.

- Frames must carry the same or higher fire rating as the door leaf.

- Certification labels must be clearly marked on the frame to validate code compliance during inspections.

Fire-Rated Frame Material Options

| Frame Material | Applications | Key Benefits |

|---|---|---|

| Steel | Commercial, industrial, high-traffic | High strength, temperature resistance |

| Aluminum-look steel | Contemporary, aesthetic installations | Sleek design with fire-rated performance |

| Reinforced wood | Select residential or retrofit uses | Customizable while meeting rating limits |

Modern steel fire-rated door frames can also be specified with narrow profiles, custom finishes, or stainless steel coatings, providing both performance and design flexibility.

Fire-Resistant Jambs: Supporting Safety at the Edges

The jambs—the side and head framing that holds the door in place—must be made from fire-rated materials such as cold-formed steel or reinforced composite. Their role is vital in:

- Supporting temperature-rise seals

- Housing smoke gaskets

- Ensuring proper engagement of self-closing devices

Careful design of jambs also allows for flush installation, acoustic insulation, or aesthetic concealment, making them suitable even in premium interior projects.

Partner with YK Fire Rated Door Manufacturer for Safety and Design

When safety and style must go hand in hand, YK fire rated door manufacturer is your trusted partner for fire-rated door solutions.

Why Choose Us:

- Code-Compliant Excellence

All our products meet or exceed NFPA, UL, and EN 1634 fire resistance standards, ensuring full compliance with international fire codes. - Custom Steel Fire Doors

We offer a wide selection of metal fire doors, steel fire resistance doors, and stainless steel fire doors, designed for both industrial durability and architectural appeal. - Tailored Design Options

Choose from various finishes, vision panel styles, and fire-rated hardware options to match your commercial or industrial project requirements. - Expert Consultation

Our technical specialists will guide you through the specification, installation, and certification process, helping you avoid non-compliant products and costly retrofits.

Final Thoughts

Fire-rated door assemblies are not just components—they are life-saving systems. Understanding the truth behind wired glass, recognizing the importance of frame compatibility, and adhering to updated code requirements ensures every part of the fire door contributes to total protection.

Don’t let outdated beliefs or legacy exemptions compromise your project.

Choose certified, tested, and fully integrated fire-rated door systems from a trusted source.

👉 Contact YK Fire Rated Door Manufacturer today to discuss your next project and get tailored solutions that meet both design aspirations and life safety codes.