Common Myths About Fire Doors – Debunked by YK Fire Door Supplier

Fire doors are critical life-saving barriers designed to delay the spread of fire, providing valuable time for evacuation and emergency response. At YK Door Industry Co., Ltd., a trusted fire door supplier and specialist in metal commercial doors, we understand the importance of separating fact from fiction when it comes to fire safety.

Whether you operate a commercial facility, manage a residential building, or oversee an industrial complex, fire doors and frames play a central role in safeguarding lives and property. Unfortunately, misconceptions about fire doors persist—misunderstandings that can compromise safety, violate codes, and risk liability.

This article from YK Fire Door Supplier addresses and corrects five of the most common myths surrounding fire doors, particularly focusing on advanced solutions such as metal fire doors, steel fire resistance doors, and stainless steel fire doors.

What Are Fire Doors?

Fire doors are not ordinary doors. They are precisely engineered safety systems constructed from materials such as steel, stainless steel, and fire-rated glass, designed to withstand high temperatures and prevent the passage of smoke and flames. However, there are many common misconceptions about fire door assemblies that can lead to improper use or misunderstanding of their critical function.

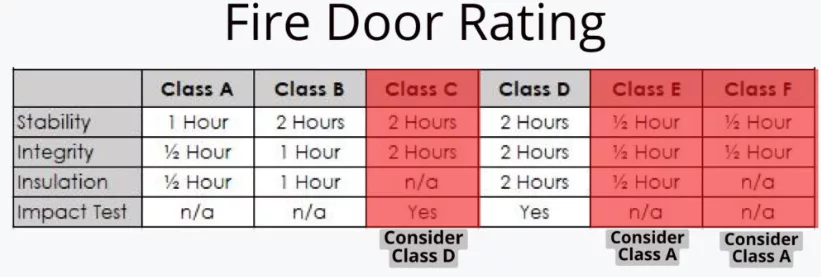

For example, a certified metal fire door can resist fire exposure for up to 30, 60, or even 90 minutes, depending on its Fire Door Rating. Commonly used materials like aluminium and steel are chosen for their thermal resistance and structural integrity under heat stress. This makes commercial metal doors especially effective in large-scale facilities where evacuation time is crucial.

YK Door Industry specializes in UL fire door systems that meet US commercial door standards, ensuring optimal performance under the most demanding conditions.

Why Are Fire Doors Essential?

Whether in apartment complexes, industrial warehouses, or public institutions, fire doors provide controlled compartmentalization of fire and smoke. Products such as the steel fire resistance door or commercial metal door with glass are designed not only to resist ignition but also to maintain structural integrity under intense pressure.

In jurisdictions like the United States, fire safety regulations mandate the installation of certified fire doors in multi-story residential and commercial properties. Each door must meet specified ratings (e.g., FD30, FD60) and bear certification labels confirming compliance with standards such as UL or NFPA.

YK’s advanced fire doors commercial line includes industrial metal doors with self-closing mechanisms, intumescent seals, and reinforced frames—features engineered to maximize both containment and durability.

5 Common Misconceptions about Fire Door – Clarified

Myth 1: Standard Doors with Fire-Resistant Paint Can Serve as Fire Doors

Reality: This is a dangerous misconception. Coating a traditional wooden or metal door with flame-resistant paint does not transform it into a certified fire door. Legitimate metal fire doors must be constructed with fire-rated cores, intumescent seals, and hardware tested to exacting standards. A simple coat of paint lacks the engineering and materials to survive sustained fire exposure.

At YK Door Industry Co., Ltd., our doors are rigorously tested and certified as UL fire doors, capable of passing stringent thermal and structural resistance tests required in the US fire door market.

Myth 2: The Gap Between Door and Frame Doesn’t Matter

Reality: The clearance between a fire door and its frame is critical for performance. If the gap exceeds regulation—typically around 3mm—it allows smoke and toxic gases to pass, undermining the door’s containment function.

This is especially vital for commercial metal doors installed in hospitals, schools, and office buildings. Fire doors commercial units from YK are manufactured with precision tolerances and come pre-fitted with compliant fire doors and frames to eliminate such risks.

Myth 3: Any Metal Lock Will Suffice for a Metal Fire Door

Reality: The lockset is a common failure point in a fire event. Even though metal doesn’t ignite, it conducts heat rapidly. Without intumescent protection and proper testing, the lock can deform and fail. Only fire-tested locking mechanisms should be used, as required by all fire door certification protocols.

Our stainless steel fire door units are paired with UL-listed hardware to ensure compatibility and safety, especially in US commercial door applications.

Myth 4: Oversized Fire Doors Can Be Trimmed to Fit

Reality: Unauthorized trimming can void the door’s fire rating. Certified steel fire resistance doors are constructed to specific dimensions, and the extent to which they can be resized is strictly defined by their certification.

If adjustments are necessary, rely on YK’s in-house installation team. We provide professional fitting services to guarantee that every commercial metal door meets both manufacturer and code requirements.

Myth 5: It’s Safe to Install Your Own Glazed Panel in a Fire Door

Reality: Cutting a fire door to insert a glass vision panel compromises the door’s integrity unless done under factory-controlled conditions using fire-rated components.

YK’s fire-rated glass metal doors offer factory-integrated glazing options, fully tested for compliance with Fire Door Ratings and US fire safety standards. Every glazed commercial metal door with glass is certified for both thermal resistance and structural performance.

Despite decades of fire safety advancements, common misconceptions about fire door assemblies still circulate widely. These misconceptions can lead to the installation of non-compliant systems, create unnecessary safety risks, and increase legal liability. At YK Door Industry Co., Ltd., a leading supplier of commercial metal doors and fire doors, we believe that safety begins with education.

Here are eight persistent fire door myths, debunked by our experts:

Myth 6: All Fire Doors Are the Same

Reality: Fire doors are not uniform in their design, construction, or fire resistance capabilities. Variations exist in material (such as stainless steel fire doors vs. timber), configurations, Fire Door Ratings, and code requirements based on building type and usage.

For instance, a metal fire door with a 90-minute rating may be essential in an industrial facility, while a steel fire resistance door rated for 30 minutes could be sufficient in a residential flat. To determine the appropriate specifications, the building’s Responsible Person must conduct a detailed fire risk assessment, which forms the basis for selecting the right door type, fire doors and frames, and certification.

Myth 7: Fire Doors Are Only Required in Commercial Buildings

Reality: While fire doors are mandatory in commercial spaces, their use extends far beyond US commercial door applications. They’re legally required in multi-storey dwellings, residential flats, loft conversions, and Houses of Multiple Occupation (HMOs).

Even in private homes, a fire door is often needed between living areas and attached garages. UL fire doors, which meet US fire safety benchmarks, are suitable for both commercial and residential buildings. At YK, our portfolio includes both industrial metal doors and fire-rated metal doors designed for mixed-use or high-density residential buildings.

Myth 8: Replacing Fire Door Parts with Standard Hardware is Acceptable

Reality: One of the common misconceptions about fire door systems is that individual parts can be replaced freely without affecting performance. In truth, fire doors are certified as complete systems. Replacing components such as hinges, closers, or locks with uncertified parts undermines their performance and voids certification. Even minor modifications can compromise the door’s ability to withstand fire and smoke.

That’s why YK fire door assemblies—including commercial metal door with glass options—are tested as integrated systems. We recommend referring to the original manufacturer’s technical sheet for any repairs or replacements.

Myth 9: Intumescent Seals Are Optional

Reality: Intumescent strips are critical to a fire door’s effectiveness. Upon exposure to heat, these seals expand to fill gaps around the door, preventing fire and hot gases from spreading to adjacent areas. Omitting them could lead to catastrophic failure and potential prosecution under fire safety laws.

Each metal fire door from YK is supplied with factory-fitted intumescent and smoke seals, precisely engineered to meet applicable Fire Door Ratings.

Myth 10: Fireproof Paint Turns Any Door into a Fire Door

Reality: Fire-retardant paint may delay flame spread by a few minutes, but it does not provide the structural resistance required of a certified fire door. A fire-rated door must undergo full-scale testing as a complete unit—including leaf, frame, hardware, seals, and any glazing—to qualify for UL fire door or similar certification.

YK’s fire doors commercial range includes fully certified assemblies that meet or exceed regulatory standards in both the US and global markets.

Myth 11: Once Installed, Fire Doors Don’t Need Further Maintenance

Reality: All fire doors require ongoing inspection and maintenance. According to BS 9999 and Regulation 10, doors should be inspected at least every six months, and in residential buildings over 11 meters high, quarterly inspections of common-area fire doors and annual checks of flat entrance doors are required.

Regular maintenance ensures your commercial metal doors continue to provide optimal protection. YK offers inspection support and retrofit solutions for worn metal doors Miami customers rely on in high-humidity and high-traffic environments.

Myth 12: Gaps Around Fire Doors Aren’t Important

Reality: Excessive gaps are a critical failure point in fire doors. Gaps larger than allowed—typically over 3mm—can allow smoke and heat to pass through, rendering the door ineffective.

Our metal fire doors are fabricated to precise tolerances and come with detailed installation instructions to maintain gap integrity. We also provide gap-checking tools and training to facility managers and installers.

Myth 13: Fire Doors Only Protect Against Fire

Reality: Smoke inhalation is the leading cause of death in structural fires. That’s why fire doors are engineered to resist not only fire but also toxic smoke.

Each YK stainless steel fire door includes integrated smoke seals, designed to restrict smoke migration and provide extra time for evacuation. These seals—distinct from intumescent strips—typically feature fins or brushes that prevent smoke infiltration, especially in fire-rated metal doors used in hospitals, airports, and high-occupancy buildings.

Expert Clarification by YK Fire Door Manufacturer

Swinging fire door assemblies play a vital role in maintaining a building’s compartmentalization, helping to contain fire and smoke within specific areas. These fire doors and frames act as critical “opening protectives” in fire-rated walls, preventing the spread of flames, toxic gases, and heat during emergencies.

Despite clear guidance in model codes and standards like NFPA 80, misunderstandings still persist in the fire protection industry. At YK Door Industry Co., Ltd., we frequently address questions from clients, architects, and contractors regarding the functionality, ratings, and installation of metal fire doors. Let’s break down some of the most common myths.

1. Wall Rating vs. Fire Door Assembly Rating

One of the common misconceptions about fire door assemblies is that the fire door’s rating must always be exactly three-quarters of the wall rating it protects. While this guideline is often used, it is not a strict rule in every scenario.

The International Building Code (IBC) outlines opening protective requirements in a table format. For instance:

- A 3-hour fire door is required in a 4-hour rated wall.

- A 90-minute metal fire door is required for 2-hour shaft enclosures.

- A 45-minute fire door may suffice for 1-hour fire barriers, depending on the wall’s location.

What’s often overlooked is that using a higher-rated fire door than what’s required is generally permissible—and sometimes beneficial. Although some Authorities Having Jurisdiction (AHJs) may prefer precise rating matches, model codes like NFPA 101 do not prohibit the use of higher-rated UL fire doors, as long as they are tested and certified appropriately.

2. Fire-Protection Rating vs. Fire-Resistance Rating

Not all fire doors are created equal in terms of performance metrics. Most metal commercial fire doors are tested for fire-protection ratings under UL 10C or NFPA 252, which assess flame and smoke resistance. However, in certain high-risk applications—such as sidelight frames in 2-hour walls—a full fire-resistance rating is required.

Fire-resistance-rated assemblies undergo testing under more stringent standards, such as ASTM E119 or UL 263, which include:

- A temperature rise limit on the non-fire side (250°F max).

- A hose-stream test to ensure structural integrity post-exposure.

Installing a fire-resistance-rated glass panel into a standard fire-protection frame is not compliant. The entire assembly must be tested together to meet code.

3. Cladding of Fire Doors and Frames

Aesthetics and fire protection often intersect—especially in commercial or luxury projects where architects specify decorative cladding or protective trim for fire-rated metal doors. However, it’s critical that these materials (often referred to as “plant-ons”) are applied in accordance with manufacturer and listing agency requirements.

According to NFPA 80:

- Plant-ons and overlays (wood, plastic, metal) must not compromise the door’s integrity.

- Only non-combustible or approved materials should be used for metal fire door frames.

- Mechanical fasteners are often prohibited; double-sided fire-rated adhesive tape is commonly required.

The frame’s UL listing mark must remain visible after any trim is applied, and cladding must not affect the fire doors and frames’ tested performance. At YK, we offer decorative UL fire doors and custom stainless steel fire doors designed for code compliance without sacrificing visual appeal.

Conclusion: Debunking Myths and Choosing the Right Fire Door Matters

A fire door is not just another door—it’s a life-saving safety barrier, engineered and certified to resist smoke, heat, and flames during an emergency. Whether for commercial buildings, industrial facilities, or multi-unit residential complexes, selecting the right fire door assembly and working with a trusted manufacturer can make all the difference.

This article has clarified several common misconceptions about fire door assemblies, including:

- Not all fire doors are the same—material, configuration, and rating must match building requirements;

- Fire-retardant paint does not turn a standard door into a certified fire door;

- Small details such as clearances, seals, and hardware directly impact a door’s performance;

- Fire doors require regular inspections and maintenance, even after installation;

- Decorative cladding must comply with tested and certified configurations;

- Fire doors protect against smoke as much as they do against flame.

As an experienced fire-rated door manufacturer, YK Door Industry Co., Ltd. delivers code-compliant metal fire doors, including steel fire resistance doors, fire-rated glass doors, and stainless steel fire doors built to meet UL, NFPA, and international standards. We serve the global market with both ready-to-ship and custom OEM solutions for commercial, industrial, and high-occupancy projects.

When You Choose the Right Door, You’re Choosing Real Protection

Understanding the common misconceptions about fire door assemblies is key to making informed, code-compliant choices. Get in touch with YK Door Industry today to explore our full range of fire-rated metal doors, discuss project-specific requirements, or request compliance documentation. Let’s build safety into every opening—starting with the right door.